DyeMansion Powerfuse S

Transform 3D printed parts into smooth, sealed, and functional end-use components with sustainable vapor polishing technology for industrial-grade manufacturing.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Transforming 3D Prints

with Precision

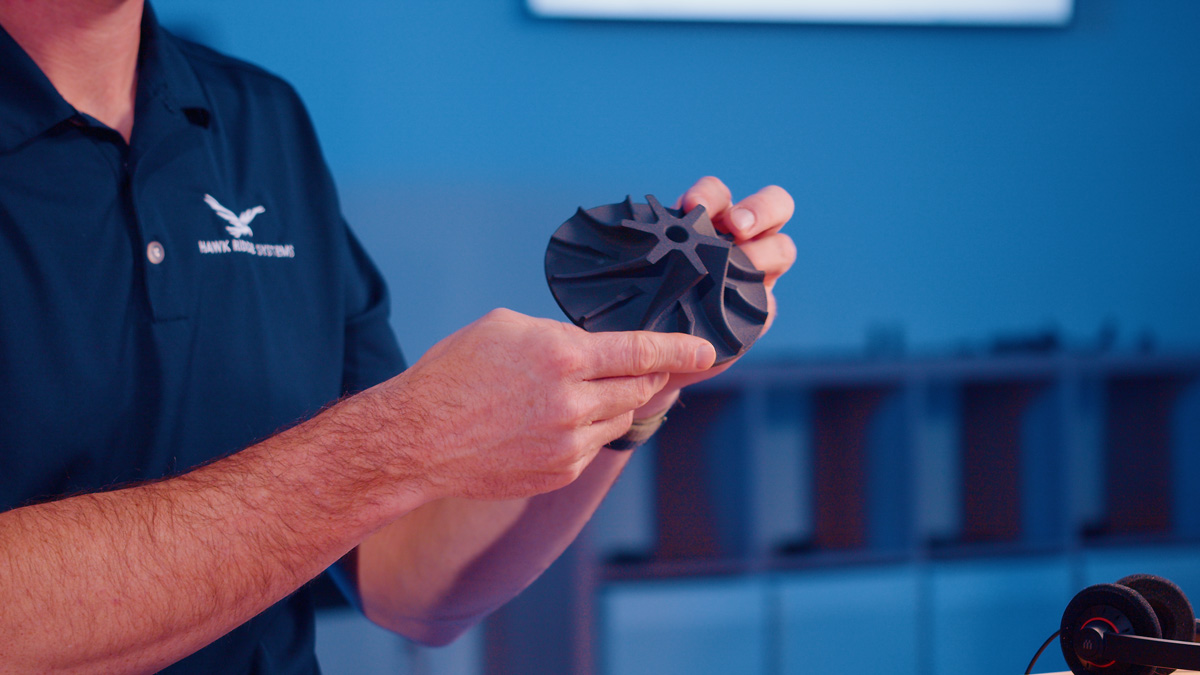

The Powerfuse S revolutionizes post-processing by delivering injection-molded quality to 3D-printed parts. Utilizing solvent-based vapor smoothing, this system creates smooth, sealed surfaces ideal for both functional and aesthetic applications. With its advanced technology, it eliminates layer lines and enhances mechanical properties, making parts suitable for end-use in demanding industries.

Designed with sustainability in mind, the Powerfuse S features a closed-loop solvent recovery system that minimizes waste and emissions. Its automated workflow reduces manual intervention, providing a scalable solution for manufacturers looking to streamline production and maintain eco-friendly operations. Whether for delicate structures or high-volume production, the Powerfuse S bridges the gap between 3D printing and traditional manufacturing.

-

Low to Mid Volume ProcessingThe Powershot C enables high-speed, automated cleaning for low or mid-volume batches. The system maximizes efficiency by minimizing operator involvement.

-

High Volume ProcessingThe Powershot C Performance is perfect for cleaning large volumes of parts, allowing operators to increase their throughput and post-processing efficiency.

-

Uninterrupted Post-Processing SolutionFor organizations looking to automate their part cleaning and surfacing processes, the Powershot Dual Performance is an ideal solution. It combines the post-processing steps into a single machine.

-

Automated CleaningMaximize efficiency with PolyShot Cleaning! Clean mid-sized build jobs in under 10 minutes. Upgrade to Powershot C for automated cleaning, replacing up to 4 manual systems.

-

Manual CleaningIn case you can’t automatically process your parts because of size or geometry, you can still manually blast your parts that require special attention

-

Ionizing UnitEliminates static dust build-up on parts.

-

Automated Loading and UnloadingThe DyeMansion Powershot Performance Series offers automated loading and unloading features, streamlining post-processing in additive manufacturing to save time and reduce manual intervention.

-

ConnectivityOPC UA interface for unidirectional communication via DyeMansion Data Connect (optional), remote support via VPN” for the Performance.

-

Pre-Installed Processing ParametersDyeMansion includes several quick-start processing programs to account for various material and part volume combinations.

Key Features & Benefits

Injection Mold Quality

Achieves smooth, sealed surfaces comparable to injection molding, making parts ideal for functional applications and end-use components with a professional finish.

Automated Operation

Streamlines post-processing by reducing manual intervention, ensuring consistent results, improving efficiency, and freeing up valuable operator time for other tasks.

Eco-Friendly Technology

Closed-loop solvent system minimizes environmental impact. PFAS-free solvent ensures safety for the operator, and non-toxic parts.

Scalable Solution

Handles large production volumes with precision and efficiency. Unbeatable cost per part due to high degree of automation and closed loop circulation with integrated solvent recovery.

Increase Mechanical Properties

Increased mechanical properties to benefit delicate structures and soft materials. Achieve an elongation at break increase by up to 200% depending on your material.

Technical Specifications

|

Features

|

Powerfuse S

|

|---|---|

|

Size

|

1305 mm x 800 mm x 1690 mm

|

|

Recommended Operational Space

|

2400 mm x 2000 mm x 2000 mm

|

|

System Weight

|

650 lbs

|

|

Power Requirements

|

230V, 50Hz or 110V, 60Hz

|

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Post-Processing Resources

Give Your Printed Part the Finished Look It Deserves

Watch Webinar

Design, Print, Ride – A Product Journey

Watch Webinar

3D Printer Buyer’s Guide

Download Guide

How Do HP Multi Jet Fusion 3D Printers Work?

Download GuideFrequently Asked Questions

It eliminates layer lines and seals surfaces, making parts suitable for functional and aesthetic applications.

The Powerfuse S works with a wide range of materials, including SLS and MJF powders. For users looking to smooth Polypropylene, DyeMansion has a separate Powerfuse S PP system.

The system uses a closed-loop solvent cycle to reduce waste and emissions.

Services & Customer Benefits

Technical Support

Our dedicated team is here to provide comprehensive support, including thorough pre-installation planning and expert installation services. By leveraging our expertise, we ensure a seamless process to swiftly set up your DyeMansion system, allowing you to get up and running with ease.

Unmatched Training

Our team is committed to your success with your new DyeMansion system. We’ll provide thorough operational training to ensure you’re fully equipped to make the most of its capabilities and seamlessly integrate it into your workflow.