Creating Threads as a true Feature in SOLIDWORKS prior to 2016 was something

of a litmus test – if you could accomplish this in a reasonable amount of time

with a few sketches and didn’t manage to ruin your model, you could probably

be hired at any company using SOLIDWORKS and hit the ground running. While not

particularly difficult to create, it did require someone to be pretty

comfortable visualizing what they wanted and to know enough about SOLIDWORKS

tools and features to combine a few tools to get the final result; in other

words, you couldn’t “Costanza” that feature, and it is a favorite amongst

engineering professors for final exams in CAD courses.

Unfortunately, or perhaps thankfully for some, the skill of manually creating

thread features may soon be on its way to becoming an esoteric CAD art-form

known only to a select few, echoing the fate of the elusive hand-drafters that

still lurk in forgotten cubicles in various industries. Why, might you ask?

Well SOLIDWORKS quietly added a new tool to the software for 2016, called the

Thread tool.

Intrigued? Imagine Hole Wizard and Weldments got friendly at a party and a few

service packs later Thread tool came out. In a nutshell, you can automatically

create full Feature threads from any of the included standards in Metric and

Imperial, cut or extruded, internal or external, left or right handed AND you

can add your own custom thread types all through an easy to

use property manager. Like Hole Wizard, you choose your Thread type and size,

any modifying parameters, and then use simple face and edge reference clicks

to quickly create your feature without any need for underlying sketches,

reference planes, or special curves. Even better, like Weldments you can add

your own custom thread profiles by creating configured sketches in exactly the

same manner you would create custom weldment profiles and adding them to the

Thread profile library folder. This way, you’re only limited by your

imagination and what you can sketch in terms of what kinds of thread you can

create using the new 2016 Thread tool.

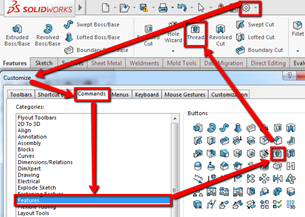

Using the Thread tool is as simple as first adding it to your Feature tab on

the Command Manager using the Customize menu, and then clicking to activate

it, as shown in the first image.

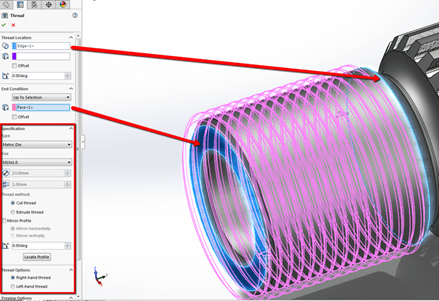

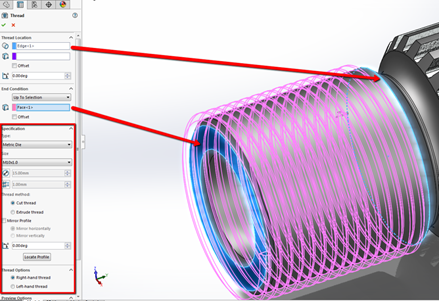

Once the property manager opens on the left, choose a circular edge to start

your thread, and an End Condition with appropriate reference selections to

finish it. In the example in image 2, we used an “Up to Selection” End

Condition and chose the face indicated by the lower arrow. The boxed area of

the property manager in image 2 is where you set the Type, Size, and other

modifying characteristics of the thread itself. Here, you can locate the

profile like a weldment, override the standard pitch and/or diameter of the

library thread profile, and even reverse the direction of the thread.

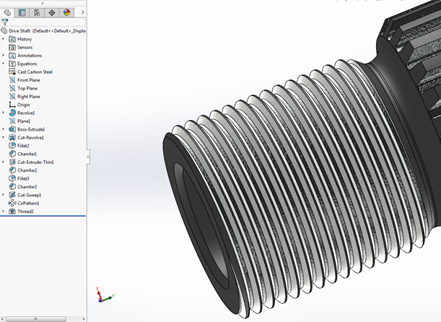

Once you’ve set the property manager to your liking, clicking the green check

mark in the upper right of the property manager will confirm the selections

and create the full featured thread, as shown in image 3. Now you can easily

create full feature threads on any part in just a few clicks, and even create

your own custom profiles. Before anyone gets too excited though, there are two

small limitations. The Thread tool does NOT yet support the creation of

tapered or pipe style threads, so the “old fashioned” ways of creating those

thread features still apply.

To find out more tips and tricks on SOLIDWORKS 2016, check out our weekly

webinars called

Webinar Wednesday.