Artec Point

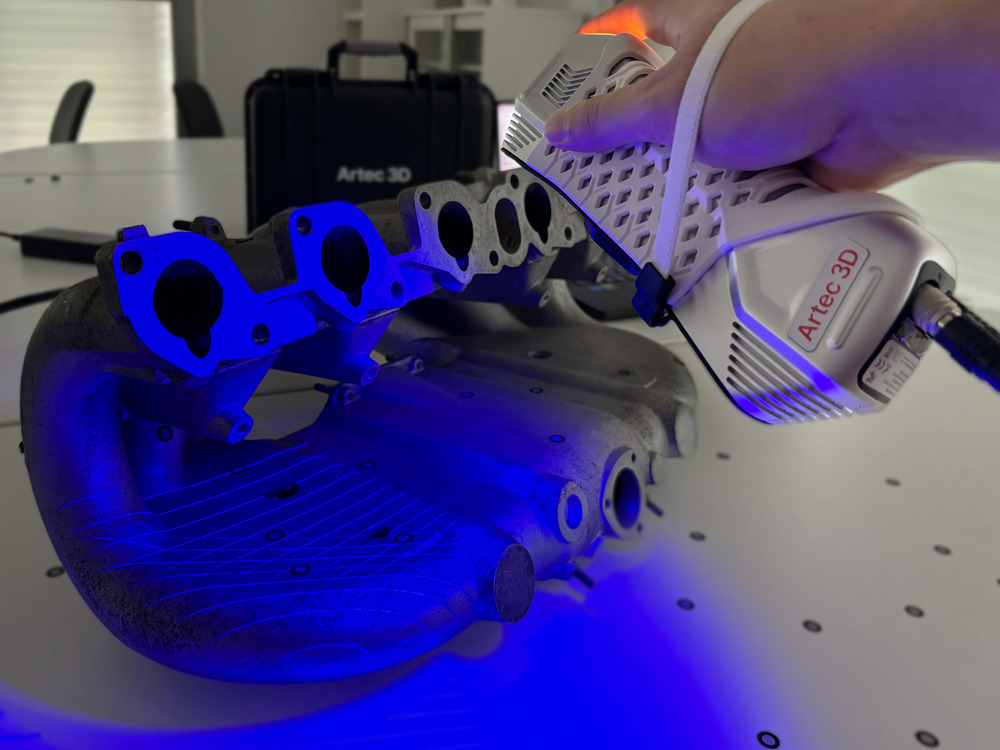

The Artec Point provides ISO-Certified, metrology-grade laser scanning to generate high-quality mesh files every time in an easy-to-use handheld scanner

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Scan Any Shape or Size Part with Confidence

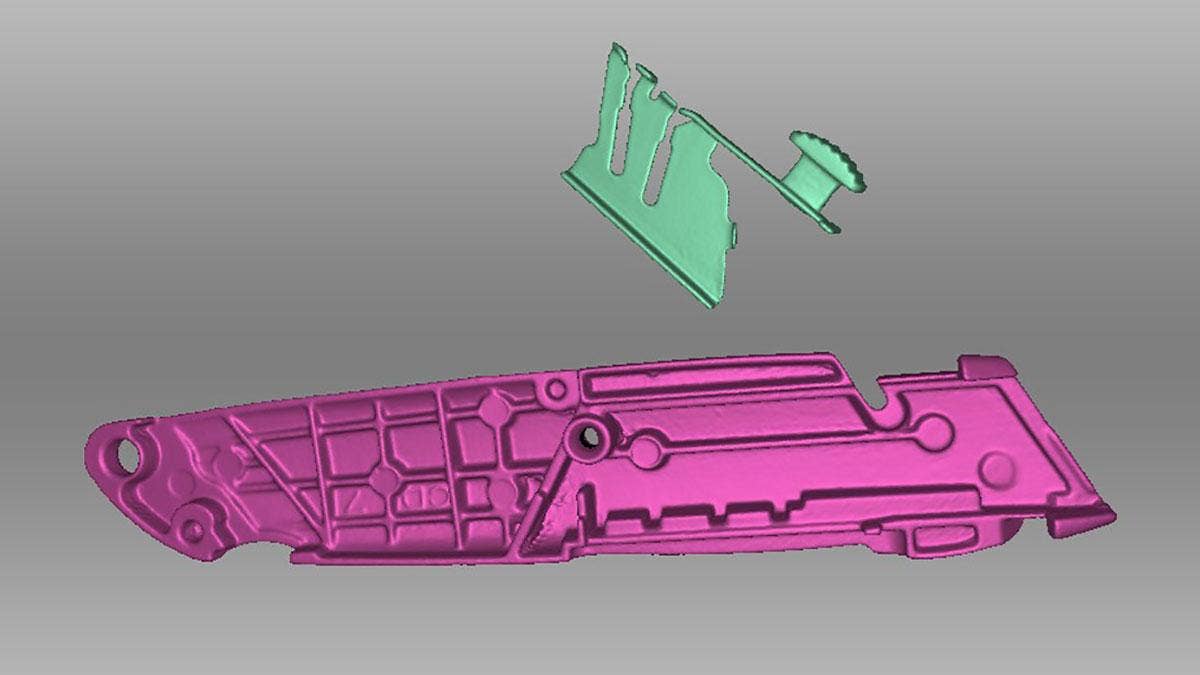

The Artec Point adds laser scanning to Artec3D’s portfolio of scanners. It brings the ability to scan complex shapes and difficult surfaces such as shiny or black easily with a laser-grid for capturing data, while maintaining a high degree of accuracy thanks to its target-based tracking system. A light but sturdy chassis and adjustable laser grid allows operators to easily maneuver the scanner into new positions and focus on the key geometry to digitize. With a scanning speed of 120 FPS and target alignment, the device can maintain its accuracy and continue to capture data while moving fast and optimally capture data in areas where the object lacks details. And with a max resolution of 0.02mm, you can display small details of your part clearly on the output mesh. With a high degree of accuracy, repeatability, and data resolution, the Artec Point is suitable for any demanding application or industry that requires metrology-grade details.

With a high degree of accuracy, repeatability, and data resolution, the Artec Point is suitable for any demanding application or industry that requires metrology-grade details.

Key Features & Benefits

0.02mm Feature Resolution

Create dense point-clouds and produce high-resolution mesh files using Artec Studio and the Artec Point. With a resolution up to 0.02mm, small features like markings, text, and edges can be displayed clearly on the output file.

ISO and VDI/VDE-Certified

Certified for advanced metrology, create inspection reports reliably and repeatability, using the data gathered with the Artec Point.

Blue-Laser Scanning with Multiple Capture Modes

Scan complex and difficult surfaces using blue-laser technology that normally would require preparation to capture. And with multiple capture modes like grid, parallel, and single-line mode, operators can capture deeper into holes or thin edges well.

Consistent Tracking and Accuracy

Using a target-based tracking system and up to 120 FPS capture speed, the Artec Point can maintain tracking across a wide-range of surfaces— allowing an operator of any skill to confidently use the scanner and capture all details of the object.

Lightweight and Strong Case

Weighing 20 oz with a comfortable grip and hard-metal casing, the Artec Point is suitable for any industrial application and space.

Larger Field of View

A 700 x 600 mm field of view allows the Artec Point to scan larger-sized objects quickly and see several targets at once to maintain tracking during the scanning process.

Usable within Artec Studio

Scan into and process data with Artec Studio – Artec3D’s premier meshing software works with all other Artec Scanners.

Technical Specifications

|

Features

|

Artec Point

|

|---|---|

|

Light Source

|

Blue Laser – Class II Eye Safe

|

|

3D Point Accuracy

|

Up to 0.02mm

|

|

Volumetric Accuracy

|

0.015mm + 0.035mm/m

|

|

Object Size

|

Small - Large

|

|

Field of View

|

700 x 600 mm

|

|

Depth of Field

|

550 mm

|

|

Scanning Speed

|

120 FPS

|

|

Tracking Method

|

Target-Based

|

|

Weight

|

570 grams

|

|

Certifications

|

ISO 17025 – based on VDI/VDE 2634 and JJF 1951

|

Artec 3D Resources

Preserving History With 3D Scanners

Download Guide

3D Scan-To-CAD: How to Model Almost Anything

Watch Webinar

The Artec Ray 3D Scanner in Extreme Environments

Read Article

Photo Textures to Your 3D Models in Artec Studio

Read ArticleFrequently Asked Questions

While the scanner does require targets to maintain tracking – it doesn’t always have to be on the part. As long as enough targets are within view on or around the part the scanner will continue to track its position and capture data.

Yes, the point-cloud generated from the Artec Point can be combined with other scanners like the Spider II, LEO, or EVA. This will add additional details to the mesh files generated by using data from both scanners in an easy-to-implement process.

By the click of a button, the device will switch the laser grid between the three scanning modes. UltraFast captures large amounts of data in less detail, Hyper-Fine increases resolution, and Hole uses a single-line laser to capture deeper into pockets.

Due to the device using a Blue-Laser the Artec Point can scan shiny, dark, or pocketed surfaces easier. These normally would require applying a dulling or opaque spray to properly capture. It also doesn’t require any re-calibration to switch between the different surfaces.

Yes, target-based laser scanning is excellent at capturing simple sheet metal surfaces with a high level of accuracy. With the multiple scanning modes thin edges can be captured and then aligned with other scans using targets on the part or matching geometry.

Services & Customer Benefits

Technical Support

Our scanning support specialists are 100% dedicated to our 3D scanning applications, have passed rigorous testing standards, and have extensive experience using our scanning products in the real world.

Unmatched Training

Every company is different, and when it comes to training for 3D scanning, one size doesn’t fit all. Hawk Ridge Systems can tailor a training plan to focus on the needs of your application.