AMT Depowdering Systems

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

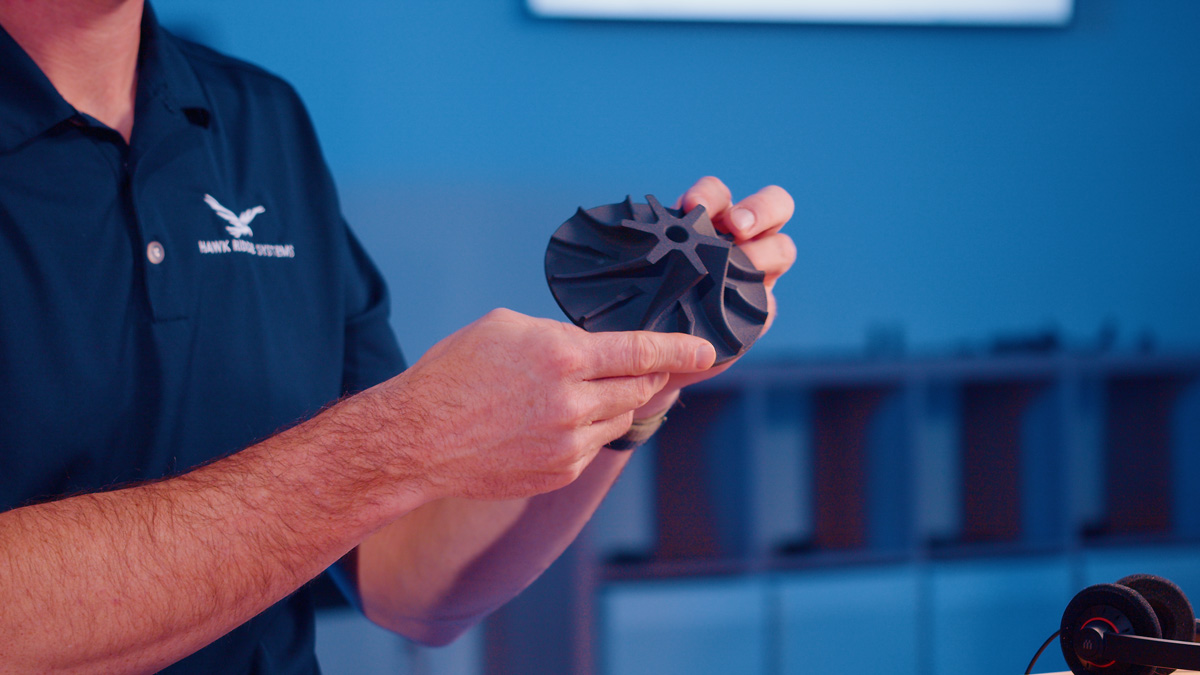

Automated Depowdering Systems for Fast Cleaning of 3D Printed Parts

Speed up your post-processing of 3D printed parts with the AMT PostPro DP, PostPro DP PRO, and PostPro DP Max. These depowdering and shot blasting systems automate the 3D part cleaning process and can even be used to improve the surface finish of parts while minimizing your labor needs. The AMT product line can be divided into 3 categories: Low Volume Prototyping, High Volume Production, and Continuous Automated Production.

The AMT industrial depowdering systems are built to last, but also designed with you in mind. Each machine is designed so that you can comfortably and efficiently operate them.

-

Low Volume Prototyping

PostPro DP gives you a large leap from manual bead blasting and makes the perfect solution to reduce human labor in your post-processing workflow. This system has high capability in an affordable package.

-

High Volume Production

If you run a lot of 3D print jobs, you will definitely benefit from the advanced efficiency features of the PostPro DP PRO. These features include removable baskets to queue multiple jobs for quick change operation, as well as in-process basket angle adjustment. The PostPro DP PRO also has the most convenient manual blasting option of any of the AMT depowdering systems with a dedicated blasting gun.

-

Continuous Automated ProductionFor lights out production, the PostPro DP Max is a 2-in-1 system of bead blasting and shot blasting. The unit uses a continuous tumbling belt perfect for both large parts and large batches of parts with 63 liters of processing volume. If you are fully committed to automation, this is the machine for you.

-

Automated Bead Blasting

-

Manual Bead Blasting

-

Removable Baskets

-

2-in-1 Shot Blasting and Bead Blasting

-

In-Process Nozzle Movement

-

Basket Angle Adjustment

-

IonizationEliminates static dust build-up on parts.

-

Cyclone Dust SeparationFiltration of media and dust.

-

Blast Cabinet Dust ExtractionVisibility

Technical Specifications

|

Features

|

PostPro DP

|

PostPro DP PRO

|

PostPro DP Max

|

|---|---|---|---|

|

Chamber Dimensions

|

52" x 37" x 42" or 1320mm x 940mm x 1060mm

|

50.7” x 41.3” x 43.3” or 1287mm x 1050mm x 1100mm

|

NA

|

|

Tumbling Method

|

Basket Tumble

|

Basket Tumble

|

Continuous Belt Tumble

|

|

Power Requirements

|

480V 3-Phase 16A

|

480V 3-Phase 25A

|

480V 3-Phase 25A

|

|

Machine Dimensions

|

64" x 63" x 87" or 1626mm x 1600mm x 2206mm

|

61” x 71” x 98” or 1700mm x 1800mm x 2500mm

|

64” x 68” x 99” (1617mm x 1725mm x 2500mm)

|

|

Bead Blast Basket/Belt Size

|

Ø 23.6" x 15.75" (Ø 600mm x 400 mm)

|

Ø 19.7" x 12.6" (Ø 500mm x 320mm)

|

Ø23” x 30” (Ø 590mm x 770mm)

|

|

Basket/Belt Processing Volume

|

30 Liter

|

20 Liter

|

63 Liter

|

|

Minimum Airflow Rate for Cabinet

|

72cfm

|

72cfm

|

106cfm

|

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Post Processing Resources

Give Your Printed Part the Finished Look It Deserves

Watch Webinar

Design, Print, Ride – A Product Journey

Watch Webinar

3D Printer Buyer’s Guide

Download GuideFrequently Asked Questions

Services & Customer Benefits

Technical Support

Our dedicated team is here to provide comprehensive support, including thorough pre-installation planning and expert installation services. By leveraging our expertise, we ensure a seamless process to swiftly set up your AMT system, allowing you to get up and running with ease.