SOLIDWORKS Inspection

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Create First Article Inspection (FAI) Reports in Minutes

The inspection process is an often overlooked, but vital step in the manufacturing process. It is essential and if something goes wrong, the consequences can be severe. But if you are creating inspection reports manually, it can be a tedious and time-consuming task.

Whether you are currently inspecting SOLIDWORKS drawings or are being provided drawings from your customers in other formats, SOLIDWORKS Inspection will help reduce the time it takes you to generate First Article Inspection reports and help eliminate human error. The software pulls data directly from SOLIDWORKS and CATIA drawings, but it can also pull data from semantic PDFs and other drawing formats without translation. SOLIDWORKS Inspection is also able to scan older drawings to extract dimensions, notes, and properties using the latest OCR (Optical Character Recognition) technology.

-

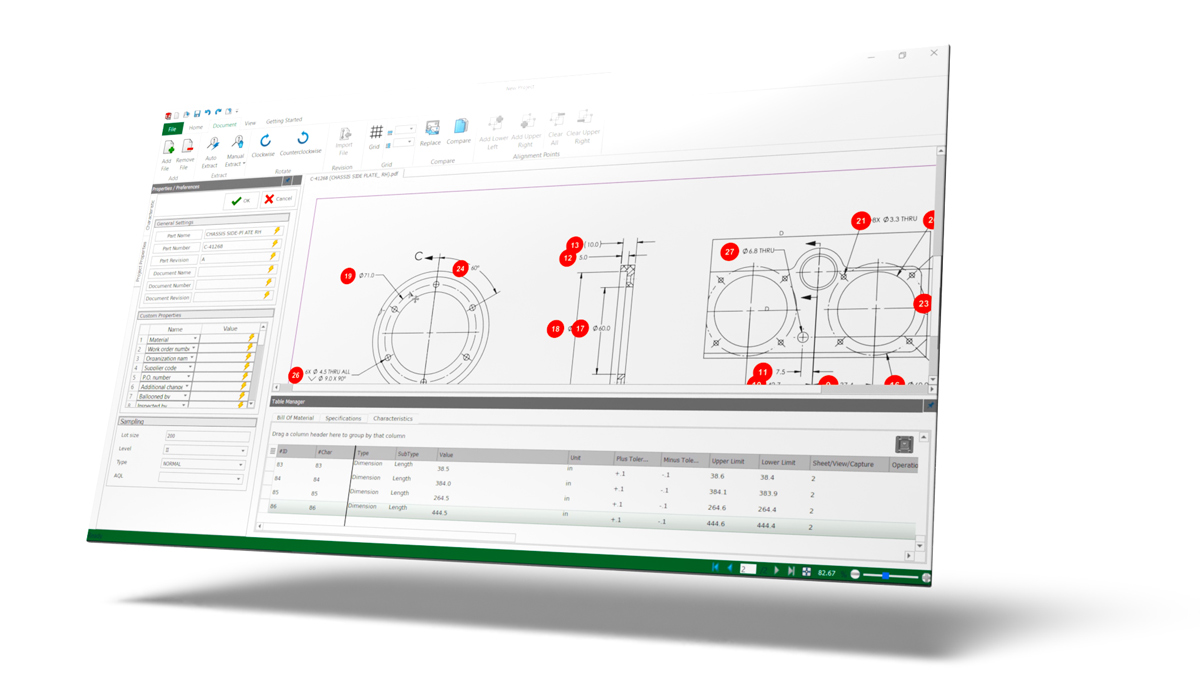

Create First Article Inspection (FAI) Report

Use the standalone application or the SOLIDWORKS add-in to quickly balloon and create inspection reports from 2D and 3D CAD, PDF, and TIFF files.

-

Automatic Ballooning

Automatically extract and balloon inspection dimensions from 2D and 3D CAD files, and specific PDF documents. Filter out specifications by anyone on design and inspection teams.

-

Optical Character Recognition (OCR)

When working with a PDF file or TIFF image, SOLIDWORKS Inspection can leverage Optical Character Recognition to read and identify the nominal dimensions, plus and minus tolerances, and the type of dimension (such as diametric or linear), helping to virtually eliminate manual input and reduce errors. It works with horizontal and vertical dimensions, split dimensions, notes, hole callouts, finish symbols, and Geometric Dimensioning and Tolerancing (GD&T) symbols.

-

PDF Drawing Comparison and 2D/3D Revision Management

Compare drawings and 2D or 3D CAD file revisions to quickly identify changes and update your quality project.

-

Enter and Import Measurements from CMM and Other Digital Measurement Devices

Enter measured values for each characteristic directly into a project either manually or by using a digital caliper. Coordinate Measuring Machine (CMM) results can also be imported.

-

Critical Dimension Highlighting

Critical Dimension Highlighting Description: Highlight dimensions in green, red, or yellow to easily identify which dimensions are in tolerance, out of tolerance, or marginally within tolerance based on the values entered.

Effortless Quality Assurance with SOLIDWORKS Inspection

SOLIDWORKS Inspection serves as a robust tool, simplifying and streamlining the quality assurance process with its array of features. By ensuring accuracy and efficiency in inspection reports, it becomes an indispensable asset for teams striving to maintain impeccable standards.

From the initial task of ballooning drawings to the final step of report generation, SOLIDWORKS Inspection provides a seamless workflow, empowering teams to achieve excellence with ease.

SOLIDWORKS Resources

What's in Each SOLIDWORKS CAD Package?

Watch Video

Top 5 Reasons to Switch to SOLIDWORKS

Read Download

Start Your SOLIDWORKS Free Trial Today

Watch Video

The Landscape of 3D CAD is Evolving

Read ArticleFrequently Asked Questions

No, but it does work directly with SOLIDWORKS drawings. Inspection is unique in that it installs as both an add-in for SOLIDWORKS and a standalone program. You get both with your Inspection purchase. The add-in inspects directly to your SOLIDWORKS drawings, and the standalone can inspect multiple drawing types such as PDF, DWG, DXF, and even CATIA drawings.

Yes. Once your First Article Inspection is ready, the standalone version of Inspection by default will import most CMM export variations. If you have any doubt, let us know and we will verify it works, or create a template so it will work before purchase.

Yes, and it runs on the same network license manager so you can have multiple people using the same license, one at a time.

Once Inspection is done gathering all bill of characteristics, CMM data, form 1, 2, and 3 info, along with any notes, tables, and page properties, it then exports as an editable Excel document and a PDF ballooned drawing. Since the FAI is an Excel document, data can be added, extracted, and the template format can be easily customized.

No. Inspection imports the results from the CMM, it does not program it.

Inspection is fully AS9102 and PPAP compliant.

Yes, they can. The add-in for SOLIDWORKS will auto-balloon the entire drawing and the standalone has what is called SmartExtract, which works with most semantic drawing formats. SmartExtract can analyze groups of dimensions and extract metadata from the drawing. This makes inspection reports fast and resistant to error.

Services & Customer Benefits

Technical Support

Our technical support team is comprised of mechanical engineers, electrical engineers, and computing specialists who provide best-in-class on-call support and Ask-an-Expert sessions when you need it the most.

Unmatched Training

We are the largest SOLIDWORKS training provider in the world, offering both online and on-demand training so your team knows how to get the most out of SOLIDWORKS.

Professional Services

Subscription Support

Whether you are looking for on-demand SolidProfessor training, access to the latest software releases, exclusive resources and offers, or just need expert support, we have a subscription option for you.