The days of drawing schematics with pen and paper, Microsoft Paint or any other general-purpose drafting tool are gone – free up your time and get projects done faster by adding these changes to your workflow.

Today, drones can deliver Amazon packages directly to your door, a piece of nano-structured glass can now store and retrieve data in 5D, but your schematic tool can’t automate repetitive tasks?

Spending days to weeks on schematic design is not just a “cost of doing business.” With technology accelerating at its dizzying pace, there are alternative options to speed up time consuming and necessary tasks so that you can focus more on design.

The Traditional Schematic Drawing Workflow

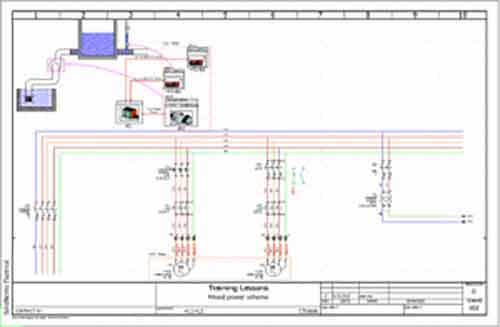

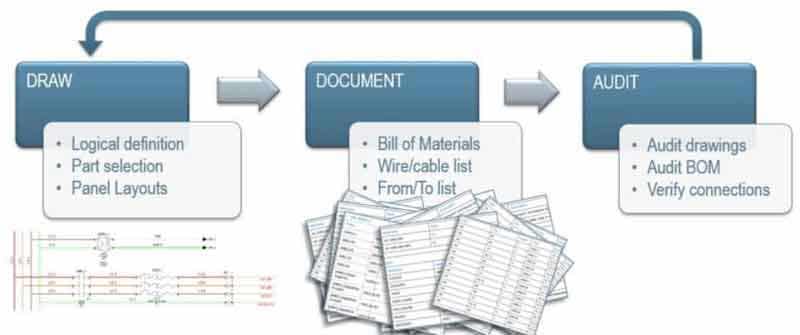

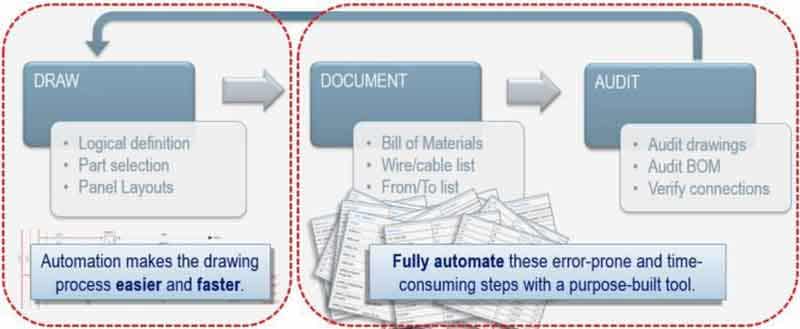

Here is what the traditional workflow for electrical schematic creation looks like:

- Create the drawings

- Generate the required documentation

- Conduct audits to verify accuracy

Create the drawings. This is the first, and most enjoyable, part of the process. Here is where you define the logic of your drawing, decide which parts are going to be used and lay out the panels in your design. The only downside to this rhythmic process is when a new part needs to be created or when an existing part needs to be reused, which happens in almost every design. Instead of a simple copy and paste or a drag and drop from a library of parts and components, these parts need to be recreated every single time they are used. This alone creates hours of work that could be saved by using a purpose-built electrical design tool.

Generate the required documentation. Designers and engineers are creatives and visionaries. You visualize solutions to existing problems and bring them to life. But the critical documentation process that comes along with great design can take days and often hinder innovation. Manually creating a bill of materials, wire and cable lists, from and to lists and more are not only time consuming but also vulnerable to human error. Transpositions can happen with a sloppy copy and paste, or a critical cell in Excel could be missed. Mistakes made during documentation can lead to unnecessary costs and rework later in the development cycle.

Conduct audits to verify accuracy. After all of your hard work creating an electrical package and organizing its corresponding documentation, it now must be audited for accuracy. Pages of schematics must be reviewed and possibly corrected. Documents need to be looked over for any mistakes and to ensure that all connections are properly mapped out. If any errors are found, which is typically the case, manual corrections then need to be made.

While the above traditional schematic design workflow is the status quo, it is also the most expensive and risky workflow for your organization. If you haven’t already heard the buzz of design automation floating around the technical world, you will soon. Automating the reporting tasks alone can save more than 50 percent of the time needed to create quality documentation while minimizing the chance of human error.

The Future of Schematic Drawing Workflow

You’ve invested a lot of time and money into your career, why get bogged down by tedious work when you can automate it?

Here are five ways automation can make your job easier:

- Reduce rework

- Preplan for projects

- Update designs in real-time throughout your entire project

- Create documentation in parallel to design

- Minimize miscommunication and maximize collaboration

Reduce rework. We’ve all experienced that sinking feeling of having to go back to the drawing board and revise a design. Now new projects are getting pushed back, and the pile of work on your desk is growing at an exponential rate. By investing in smart technology with automation, you can keep a comprehensive project history with snapshots and revision control easily on hand to quickly fix designs so that you can move on to new projects faster.

Never start a project from a blank sheet of paper (physically or virtually) again. Automation allows you easily grab existing parts and components that you’ve previously built, or quickly download the new ones that you need. Customizable templates and libraries allow you to pull popular parts, schematic pages or even complete projects with ease so that you can quickly hit the ground running with even the most challenging projects.

Preplan for projects. How many times have you created the most ingenious design, only to learn that the lead time for a particular part is months out? With a robust, electrical-centric software program you will know exactly which parts you need in advance and have them ordered well before they are needed. Designs can get approved earlier, sent to manufacturing faster and delivered to customers on time!

Update designs in real-time throughout your entire project. We’ve all been there – one design change needs to be made, and for the next thirty minutes you’re frantically flipping through pages of the schematic and opening different programs to update all of its related documents. And the process is repeated for every single design change throughout your project.

With intelligent software, one change updates everywhere throughout your entire project. This includes updating all your related documents and reports. No more spending countless hours updating changes in multiple places and hoping you didn’t forget something.

Create documentation in parallel to design. The benefits of automated reporting are invaluable. Merge the last two steps of the traditional electrical drawing workflow into step one: create the drawings. These three steps can be done simultaneously. Documents are created and updated as you design, and with one click you can audit your documents to guarantee they are up-to-date and accurate.

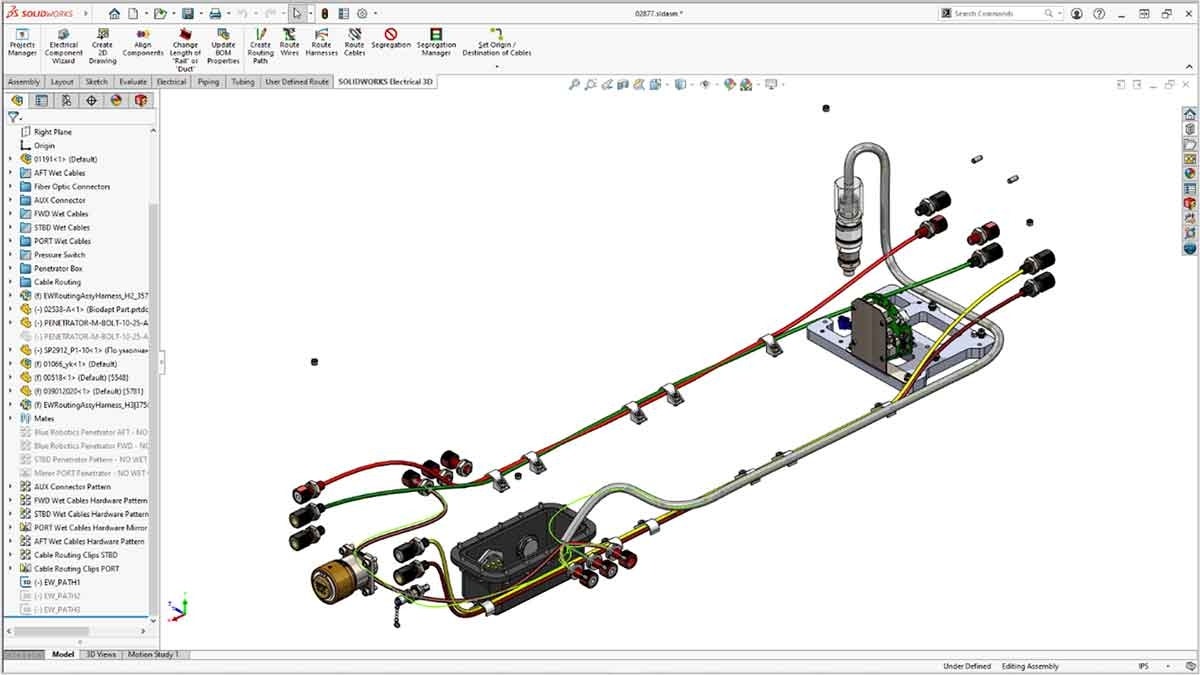

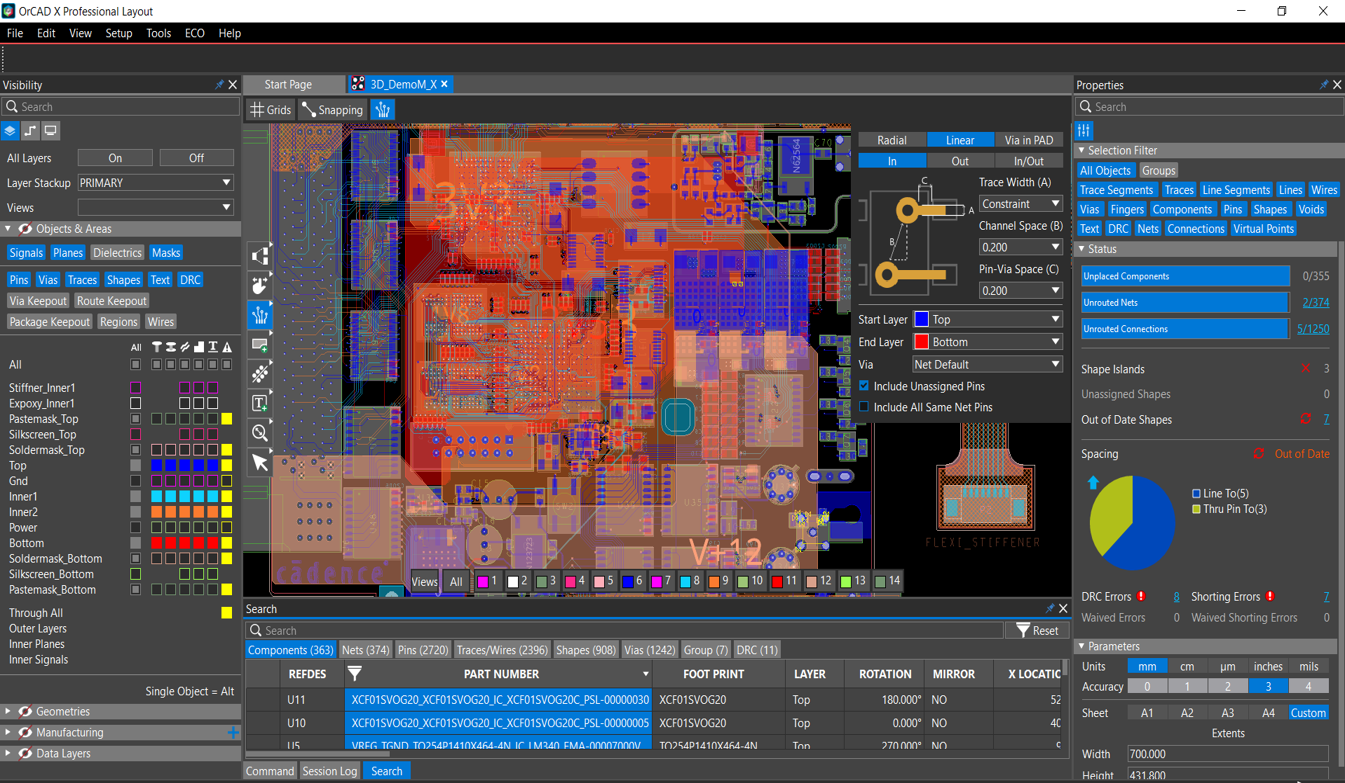

Minimize miscommunication and maximize collaboration. Whether you work with an electrical engineering team, a team of electrical and mechanical engineers, with different departments or by yourself, the ability to easily share files paired with the bidirectional synchronization between mechanical and electrical design is revolutionary. Specialized engineering software allows you to save multiple revisions for various iterations until you get the design just right, and you can see revisions and changes in real-time. This means the mechanical team can see the electrical changes, and the electrical team can see the mechanical changes — eliminating the confusion from working with older versions.

Working with intelligent software has many benefits that not only strengthen your design but also make your life a lot easier! If you have any questions about how you can use SOLIDWORKS Electrical products to achieve design automation, contact us at Hawk Ridge Systems today. Thanks for reading!