Manufacturing costs are escalating in part due to material prices, supply chain breakdowns, along with labor cost increases and shortages. When adding shop personnel, we’re often faced with the challenge of trying to outbid the company down the street for the next seasoned machinist, or building up a candidate with less experience. Unfortunately for many shops, by the time these workers are fully trained, they move on to the next higher offer, taking their expertise with them.

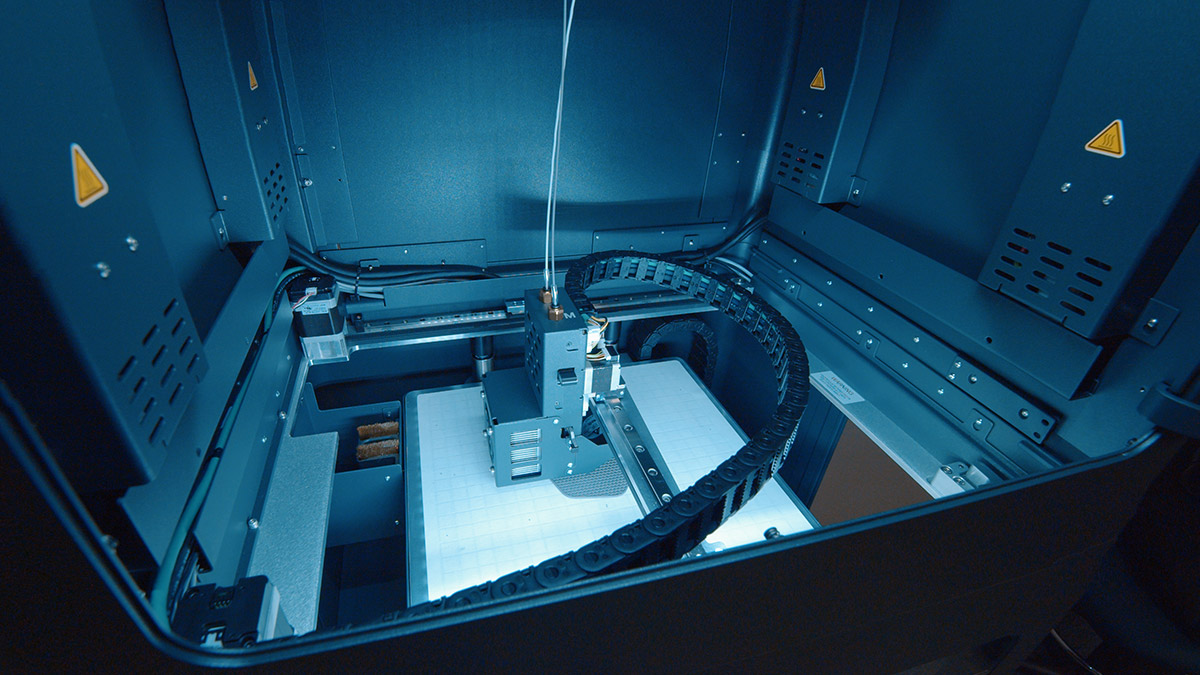

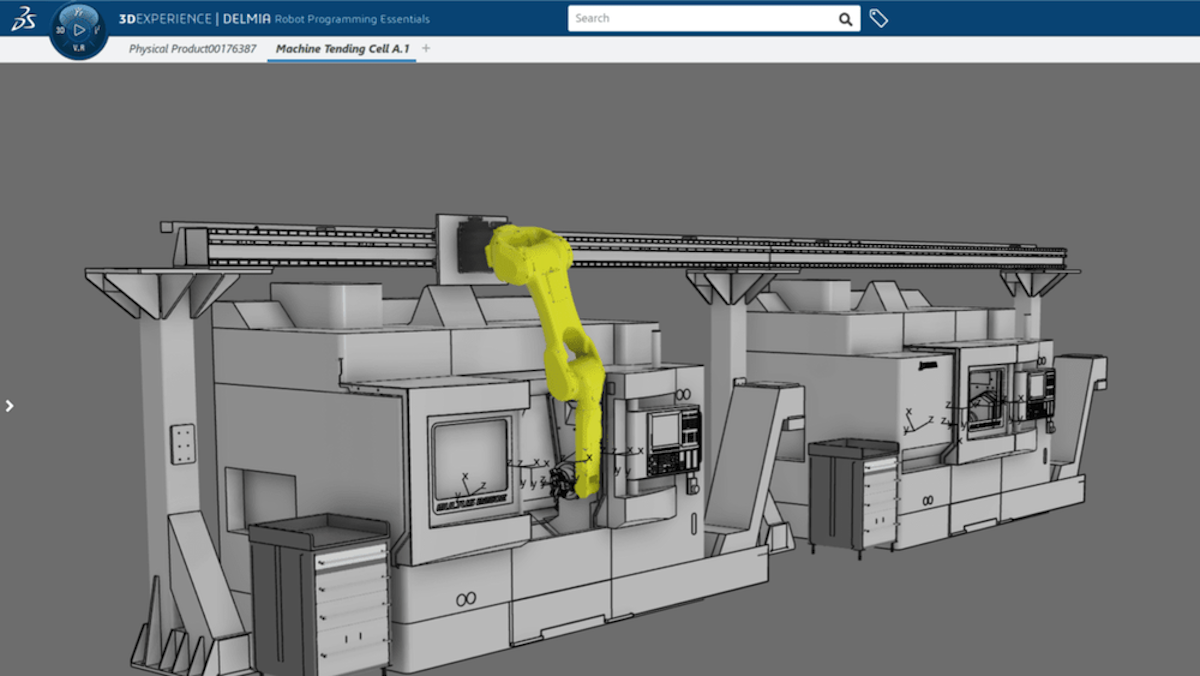

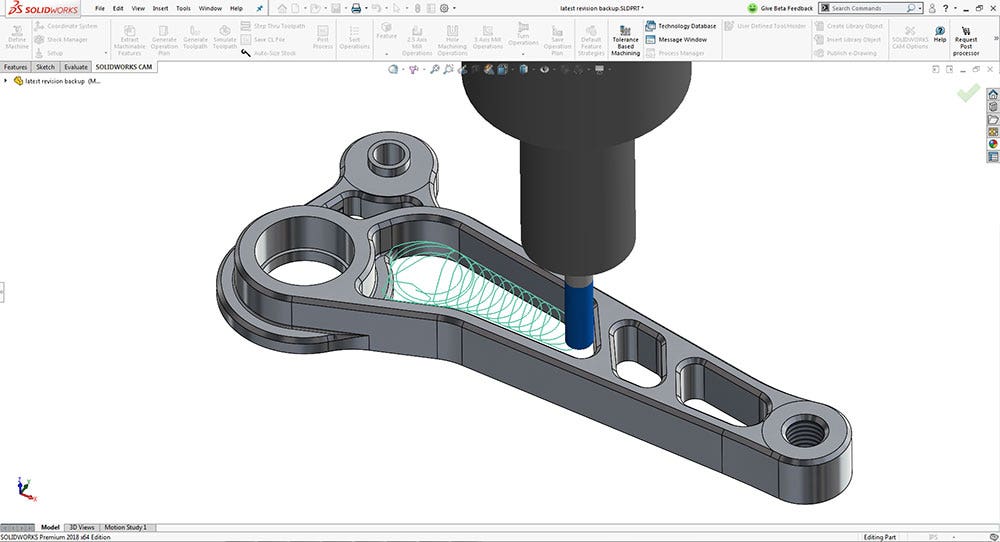

With all these challenges, it’s more critical than ever to leverage software tools that can accelerate your shop’s throughput with greater efficiency. Running natively inside the SOLIDWORKS user interface, SOLIDWORKS CAM and CAMWorks have built-in advantages for manufacturers to do just that.

Pass On Your CNC Machining Best Practices

Adding integrated machining software like CAMWorks or SOLIDWORKS CAM can help you bridge the skills gap in your workforce. These tools allow seasoned professionals to easily share your company’s machining best practices with entry level CNC programmers. And, when someone moves into a new role, you’ll have captured those best practices in the imbedded Technology Databases, making that information easily sharable with your next CNC programmer or even your apprentices.

Increase Machine Shop Efficiency

Beyond the sharing of best practices, integrating CAM software helps to further increase your shop’s efficiency through:

- Automatic Feature Recognition (AFR): automatically analyze any 3D solid model and return machinable features

- Associativity: create toolpaths that adapt to changes in the CAD model including Engineering Change Orders (ECOs)

- Model Based Definition (MBD) & Tolerance Based Machining (TBM): tolerances will influence machining and live on within the model, not in some dirty drawing on the shop floor

- Ultra-high efficiency tool paths deliver optimum material removal in both milling and turning

These capabilities all reside inside SOLIDWORKS, the most popular solid modeling CAD package in history. If you’d like to learn more, don’t miss our upcoming webinar, “5 Ways CAMWorks & SOLIDWORKS CAM Accelerate CNC Programming.”

Missed the webinar live? You can watch the recording here.

You can also contact us at Hawk Ridge Systems and speak to our experienced CAM team about how CAMWorks and SOLIDWORKS CAM can impact your company’s machining trajectory. Thanks for reading!