Over five years ago, manufacturers feared that the adoption of 3D printing technology wasn’t happening fast enough in higher education. Today we’re telling a different story because universities are investing in additive manufacturing left and right. Leading universities specifically, are not just opting for desktop units though … the most competitive schools are investing in metal.

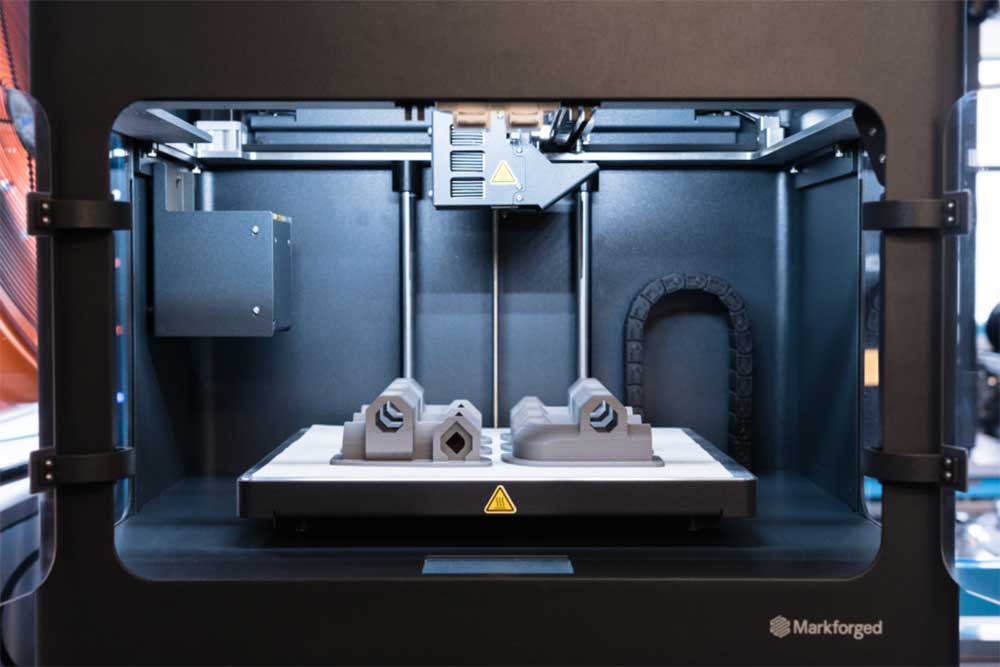

The Markforged Metal X is a perfect example of a 3D printer that meets the needs of even the most selective colleges and universities. With its price point, uniquely safe process, and impressively strong parts … this metal 3D printer is a no-brainer.

Price

The average metal 3D printer can set you back $250,000 to one million, but the Markforged Metal X is just shy of six figures. This allows colleges and universities to stay within their budgets while still giving them ample room to build dedicated spaces and or, additional resources. What would you do if you saved nearly 10x of your anticipated spend: invest in another printer or build a print farm for your students? The possibilities are endless.

Process

Many colleges and universities have invested in metal 3D printing to only see those units depreciate with little to no use. This can be accredited to what process, or type of 3D printing they invested in.

Traditional metal 3D printers often use a technology called Direct Metal Laser Sintering (DMLS). DMLS can be defined as a process where a laser makes a 2D design on a flattened powder bed and that design is pushed up. The laser then, repeats this process continually until a 3D part is curated.

As you can imagine it’s quite time consuming, but that’s not the only issue. Student safety is a cause for concern since this process requires special handling. Toxic fumes fill the air requiring students to wear special equipment and follow very strict instructions for operation. Is it any surprise then, that the risk is not worth the reward? Between time and safety, a lot of institutions don’t truly capitalize on these 3D printers. A large amount of them don’t get nearly enough use.

On the contrary, the Markforged Metal X is more reliable and compliant because it uses a different process altogether. With a Metal X you’re printing metal powder bound in a plastic matrix. This makes it not only safe but also allowing you to optimize with features like closed-cell infill for reduced part weight and cost. The safety, ease, and time savings from the Markforged unit ensure that the printing queue always be tied up. Constant use is constant reassurance that you’ve made the right investment.

Parts

The proof is in the pudding. When it comes to 3D printing, the Markforged Metal X has an impressive materials portfolio. You can print in five metals, three of which are tool steels, and there’s no sign that product development has any intentions of slowing down anytime soon. Every material opens up new applications, including 17-4 Stainless Steel, H13 Tool Steel, A2 Tool Steel, D2 Tool Steel, and Inconel 625. No matter which material you choose, you can always rely on Markforged for durable parts.

If you’re ready to provide your students with top of the line equipment, then look no further. Hawk Ridge Systems is dedicated to helping colleges and universities develop their 3D printing strategy. When the future of our country is on the receiving end, we want nothing but the best. Contact us and our team of additive manufacturing experts can help you get started today!