This is part 3 of a 3 part discussion. Check out parts 1 and 2 using the links below:

In this post, we’re going to take symmetry one step further and explore using 2D simplification studies. 2D simplification studies are a feature of SOLIDWORKS Simulation Professional and can be used to dramatically reduce the amount of time needed to solve a problem. 3D models can be simplified to 2D in plane stress, plane strain, or axi-symmetric situations. Since we’re expanding on the topic of symmetry, we’ll focus on axi-symmetric 2D simplification here.

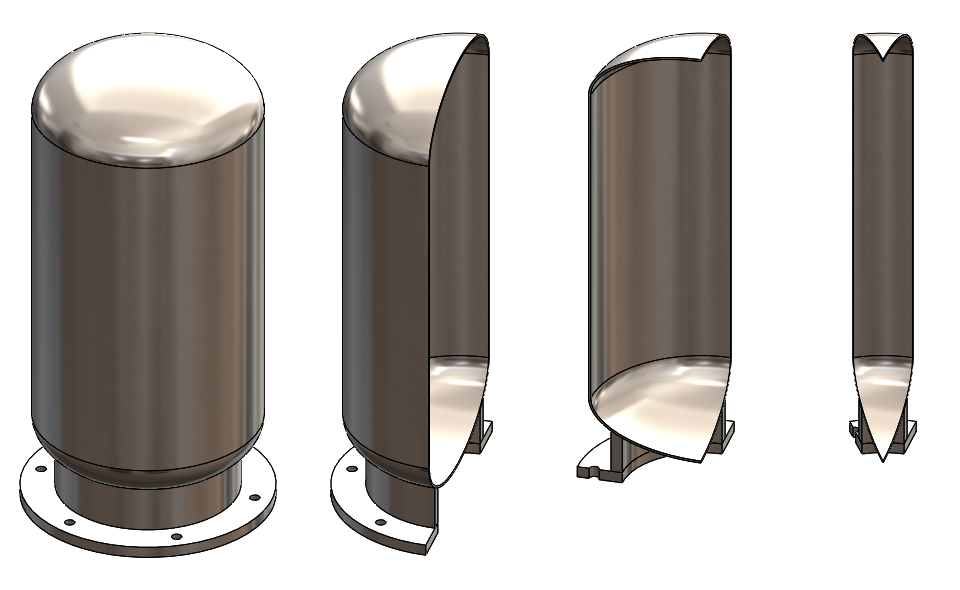

In part 2, we took advantage of symmetry to reduce a cylindrical tank to a 30 degree slice. The holes in the base limited how small of a slice we were able to use. But if we assume that the overall structural effect of these holes on the critical areas of the tank walls is negligible and suppress the holes, there’s no limit to how small we can slice. We can use a 10 degree slice, a 1 degree slice, or with 2D simplification, even a 0 degree slice.

2D simplification studies can be defined by checking the option at the bottom of the PropertyManager when creating a new study. For axi-symmetric situations, the 2D slice is defined with a section plane and axis of symmetry.

The study can be set up as usual, but since the 2D simplification definition takes care of the axi-symmetry for us, there is no need for any symmetry restraints.

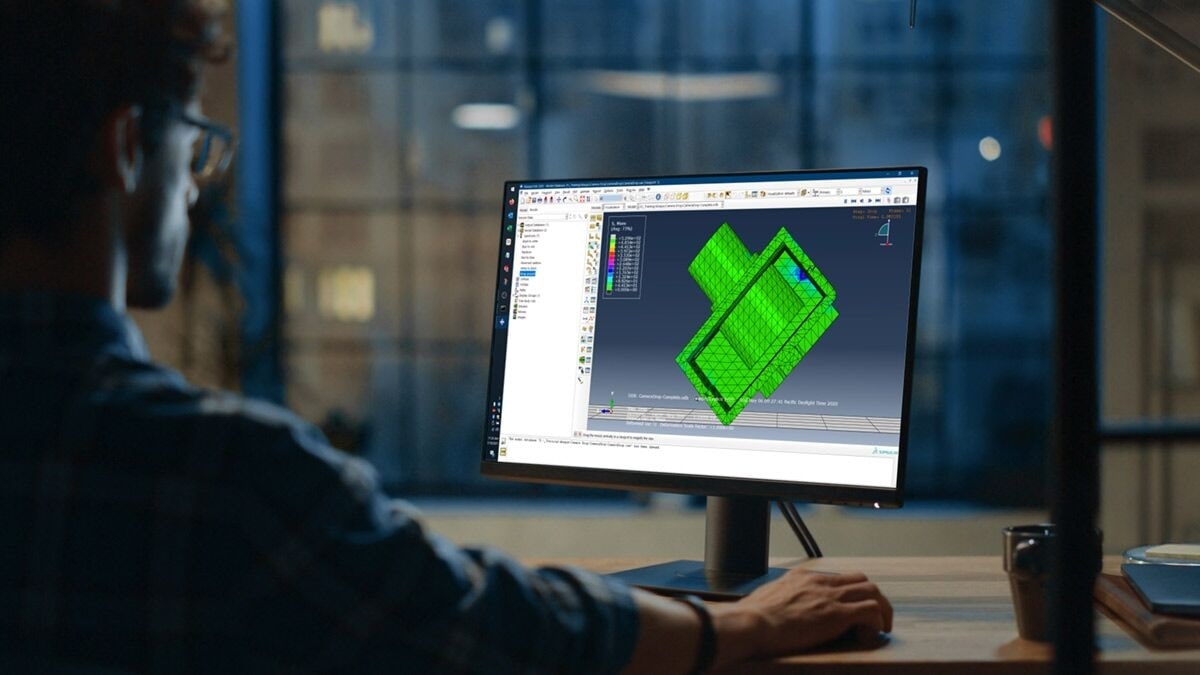

Once the study has been run, the results can be viewed on the 2D slice using the same plots and tools as usual. There is also the option to show the results as a 3D plot if you’re feeling fancy.

Comparing this 2D study with the 3D study shows just how efficient 2D simplification is. At the same mesh size, the 2D study has less than 1% of the number of mesh elements, and even with a refined mesh, takes less than 1 second to solve.

So that wraps up our discussion on symmetry in SOLIDWORKS Simulation. I hope these posts will help you use symmetry to create more efficient studies. For more information and Simulation tips, visit our SOLIDWORKS Simulation page, Get a Quote or check out our YouTube Channel. Thanks for reading!