The endeavor of automation, whether for simple, repetitive tasks or those more complex and less frequent, is arguably one of the most exemplary characteristics of modern engineering.

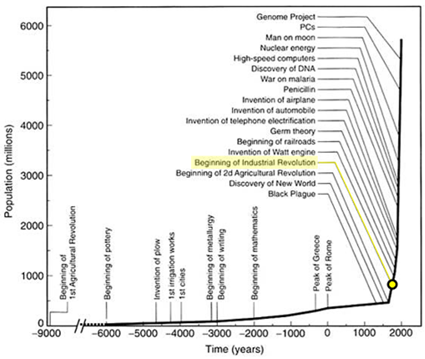

With roots tracing back over two thousand years to the development of the automated water clock for the accurate measurement of time, automation would eventually fuel the industrial revolution in the 18th and 19th centuries and the subsequent development of steam power, machine tools, advanced transportation systems, and automated agricultural process, along with many other technological developments.

These developments ultimately resulted in improved living standards, including access to food and water, housing conditions, public health, a precipitous increase in literacy, and the capacity to support a massively expanding world population.

The topic of life sciences is vast, encompassing biology, anatomy, botany, neuroscience, and dozens of additional sciences related to the study of living organisms. Similarly, Applied Life Sciences focuses on the same list of subjects, with one key difference – how might the findings of these sciences be utilized and applied through engineering to improve our standard of living further?

In this article, we examine the intersection of these two subjects: how is automation being leveraged in Applied Life Sciences to improve the lives of everyday humans?

We’ll investigate two specific case studies in which DriveWorks configuration and automation software is used with SOLIDWORKS CAD to quickly customize and produce unique design and manufacturing data in the agricultural/food processing and medical device industries.

What Are SOLIDWORKS CAD and DriveWorks?

Before we begin, it’s important to understand the basic functions of both SOLIDWORKS 3D CAD and DriveWorks configuration software.

- SOLIDWORKS is a parametric, feature-based CAD system used worldwide to design, validate, and manufacture products across dozens of industries, from art installations and jewelry to aerospace components.

- DriveWorks is an add-in to SOLIDWORKS, allowing engineers and designers to establish rules and logic by which these designs must abide. These rules, along with simple input forms that accept critical design parameters, allow for rapid iteration of customizable products which are similar but different enough to require unique manufacturing data.

How Do You Use DriveWorks?

Using a DriveWorks project typically results in a full model set, along with any required manufacturing drawings, itemized quotes, bills of materials (BOM), and cover letters for communicating with customers.

DriveWorks projects can also be scaled up to allow configuration by non-technical staff or even the consumer directly through an online platform. Combined, SOLIDWORKS and DriveWorks are uniquely positioned to reduce design and manufacturing time while improving product consistency and quality by reducing the potential for human error.

Case Study 1: Creating Beautiful, Custom 3D-Printed Writing Aids for Individuals with Cerebral and Physical Disorders

Company: OpenDot FabLab and TOG (Together To Go) Foundation

Industry: Medical

Challenge: Creating aesthetically pleasing, custom writing aids for children with complex neurological and physical disorders

Solution: DriveWorks Professional offered biometric design options for OpenDot FabLab and TOG (Together To Go) Foundation to create a fully customized writing aid for children with disabilities.

For our first case study about Glifo, SOLIDWORKS is used in conjunction with DriveWorks in the medical device industry to simplify and expedite the design and manufacturing of custom writing aids for children with complex neurological and physical disorders.

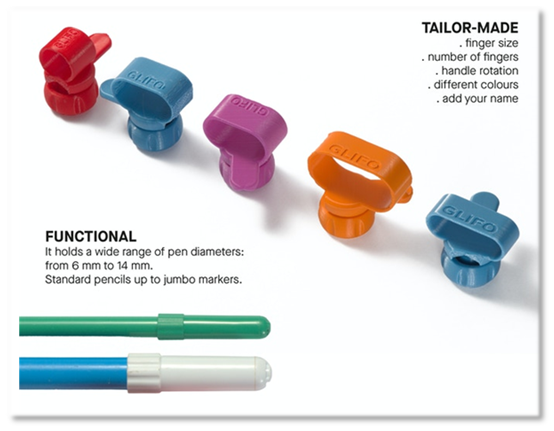

Glifo, a custom writing aid, was founded in 2014 through the collaboration of designers, manufacturers, therapists, students, and families of children with physical and neurological disorders.

Their goal to develop a device allowing these children to use a writing instrument had been done before, but existing designs were adjustable rather than fitted to the individual user, making them more difficult to use. Additionally, to put it plainly, existing designs were aesthetically boring and often failed to connect with younger users.

The team aimed to develop a fully-customizable solution, bespoke for each individual user, with options for size, handle rotation, color, and even an imprinted name to improve function and comfort while encouraging use by children.

Importantly, the design needed to be affordable to make it available to as many users as possible.

3 Challenges in Developing Custom Writing Aids for Children with Disabilities

Developing a single iteration of a writing aid is quite an undertaking in and of itself. However, the custom nature of the device meant that any models, drawings, and/or 3D printing data would need to be adjusted for every individual user, resulting in an unsustainable design time that could not be easily scaled to meet demand and an unnecessarily high price point. Fortunately, despite the unique nature of each iteration, each Glifo writing aid design can be described by the same few parameters:

- How many fingers will be used to hold the device?

- How large are these fingers?

- What is the inclination (rotation) of the hand while writing?

Answering these three simple questions provides all the necessary design information to create a custom-fit Glifo for a new user. However, adjusting all the design and manufacturing data to fit these parameters is a tedious and repetitive task contributing to the design time and the overall price. So, DriveWorks was introduced to the team at Glifo.

DriveWorks Made Customization Possible for Glifo

To successfully capture the rules and logic of the Glifo design as a DriveWorks project, it needed input on the number/size of fingers, handle rotation, color, and imprinted name. Using DriveWorks, the team did it in a simple five-step form.

Using the original iteration of Glifo as a “master model,” these parameters are updated, and new design files, including SOLIDWORKS parts, assemblies, and drawings, are automatically produced, which improves manufacturing capacity while dramatically reducing design/manufacturing time and subsequently, cost to the user.

The result is a custom-fit, personalized writing aid for children at the lowest possible price point, improving product quality and access in underserved communities.

The last remaining obstacle for Glifo to address was the ease of configurability. Initially, customers were required to have in-person visits and measurements taken for those parameters so the team could complete the DriveWorks model for design and manufacturing.

In 2020, Glifo launched a fundraising campaign to develop an online configurator powered by DriveWorks Live, an extension of DriveWorks Professional, to allow families and children with disabilities to configure their own products directly online without leaving their homes.

Glifo is just one of many examples of successful DriveWorks implementation in Applied Life Sciences.

Case Study 2: Reduced Engineering Time Is a Winning Recipe for a Bakery Equipment Manufacturer

Company: Rademaker

Industry: Food Processing

Challenge: Creating custom industrial bakery solutions require time and effort to produce

Solution: DriveWorks Professional allowed Rademaker to automate design work in 15 minutes per iteration for modular units and integrated well with its existing SAP Product Lifecycle Management system.

For our second case study about Rademaker, we examine the impact of DriveWorks automation in the agricultural and food processing industry.

Founded in 1977, Rademaker has decades of experience specializing in developing food processing systems for the bakery industry.

These complex systems include fully-featured production lines for bread, pastries, pizza and pie crusts, croissants, and other artisan bakery products.

Naturally, these products vary significantly in shape, size, and consistency, so the production equipment must be customized to meet these needs. Some products are produced whole, and some are sliced, perforated, rolled, or laminated, each requiring different mechanisms for production.

Even within a given product line, offering customers the option to customize the equipment size and order of operations for modular systems is critical to winning business and providing world-class industrial baking solutions.

How Rademaker Achieved Its Pie in the Sky Goal with DriveWorks Professional

As one would expect, the engineering time and effort required to prepare an order for a custom production line was originally very significant, as SOLIDWORKS models were copied and updated by hand to produce the required models, drawings, and bills of materials (BOM) for manufacturing.

Excessive engineering time from these repetitive tasks not only cuts into profit margins but also increases the response time to requests for quotes, potentially losing business to fast-acting competitors.

However, despite the relative complexity of these systems — when compared to a device such as Glifo, the production line assemblies designed by Rademaker can still be defined (in majority) by a specific set of parameters due to their modular nature.

Characteristics, such as the working width of conveyors, desired shape and internal structure of dough, fillings, and throughput requirements, work together to dictate the system’s design.

Conveniently, these parameters are captured in a simple input form, like the measurements required for the Gilfo writing aid. Rademaker can automate the generation of required manufacturing data for these highly customized systems, greatly reducing engineering time.

As one might expect, exceptionally complex or custom orders may require some degree of manual intervention, but note that implementing DriveWorks Professional has allowed Rademaker to automate the vast majority of design work — resulting in an average engineering time of only 15 minutes per iteration for modular units, even for highly customized systems.

In addition, DriveWorks was seamlessly integrated with Rademaker’s existing SAP Product Lifecycle Management system, allowing them to standardize change control, logistics, and sales processes, further reducing overall production time.

Ultimately, this dramatic improvement in efficiency has allowed Rademaker to expand their product offerings with the ability to handle a greater number of product functions and variations.

Rademaker is a prime example of the product cost and quality benefits that DriveWorks can help solve for complex systems.

Is DriveWorks Right for Your Business?

The DriveWorks team at Hawk Ridge Systems has decades of combined experience in project development and automation. The expert team works with customers across various industries to successfully implement DriveWorks based on our customers’ unique requirements.

Before implementing DriveWorks to automate design and manufacturing data, you will need a strong knowledge base of its capabilities and a clear understanding of the design parameters you need to automate your products.

Whether you’re looking to develop a simple customizable product or create an online configurator to process thousands of complex orders, Hawk Ridge Systems offers the tools, training, and expertise to guide you through successful project development and implementation.

For more information on DriveWorks products or to schedule a consultation, contact us at Hawk Ridge Systems today. Thanks for reading!