Welcome to my second article in this series on using TolAnalyst for

assemblies. In this second article, I’m going to set up a tolerance analysis

so that you can see what’s involved. Before going any further, if you haven’t

done so already,

please read Part 1 of this series. Go ahead, I’ll wait…

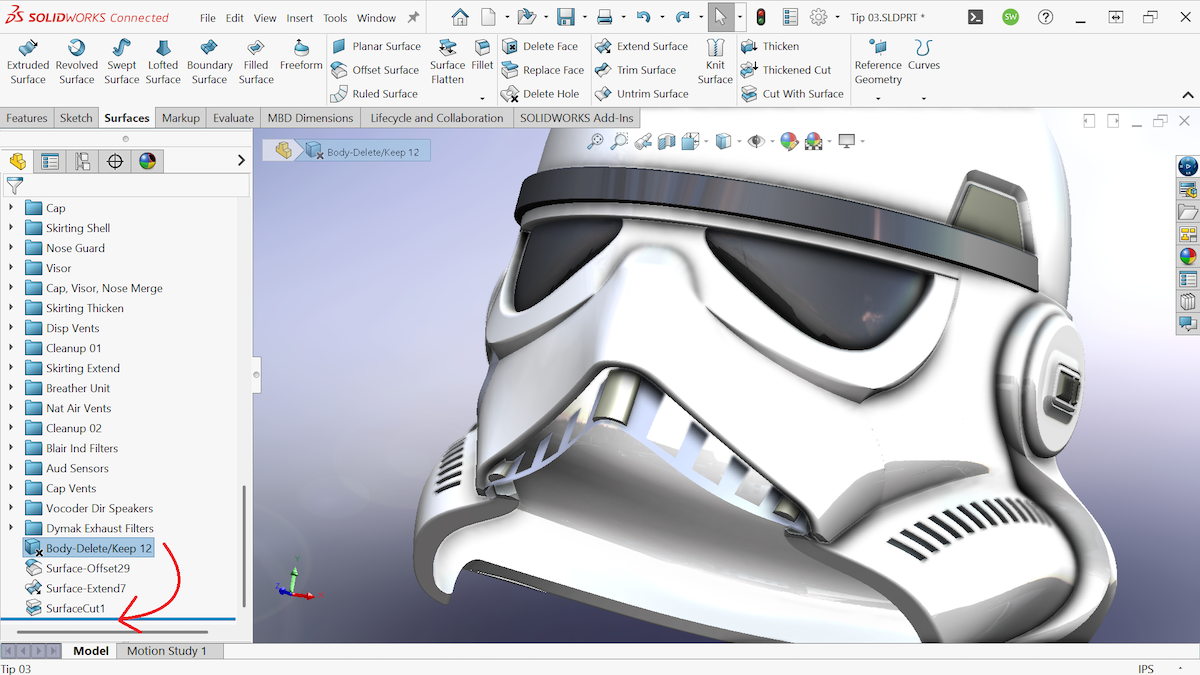

Okay, now that’s out of the way, let’s go back into this “sheeter” assembly.

All of my parts have DimXpert dimensions and tolerances, so I can start my

TolAnalyst study to make sure the knives don’t bind together and aren’t too

far apart. In this case, over ¼” apart would be too far because the assembly

won’t cut a sheet at that point.

There is a 4 part process to our study:

- Define the measurement you want to control.

- Define the assembly sequence.

- Define the assembly constraints.

- Run the analysis and adjust the tolerances as necessary.

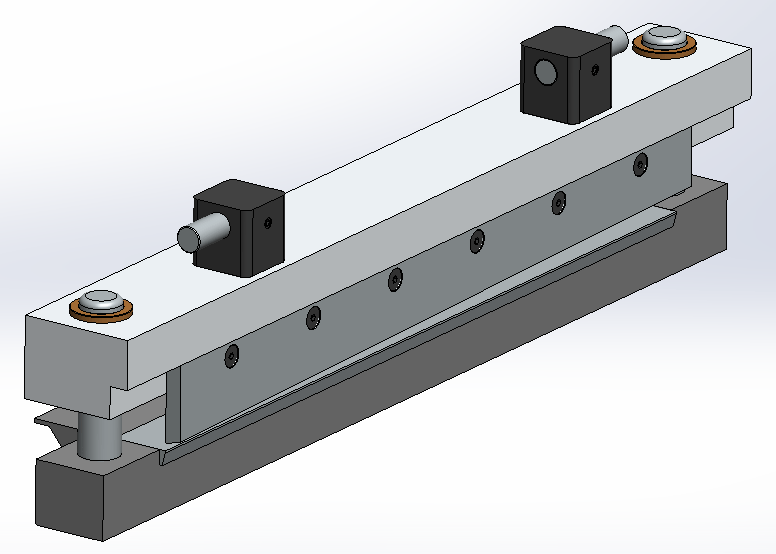

This article will cover Steps 1 through 3, and the last article in the series

will cover running the analysis and refining the results. To start the study,

click on the DimXpert Manager tab and click the TolAnalyst icon. (Remember, if

this isn’t available, make sure that TolAnalyst is turned on as an Add-in.)

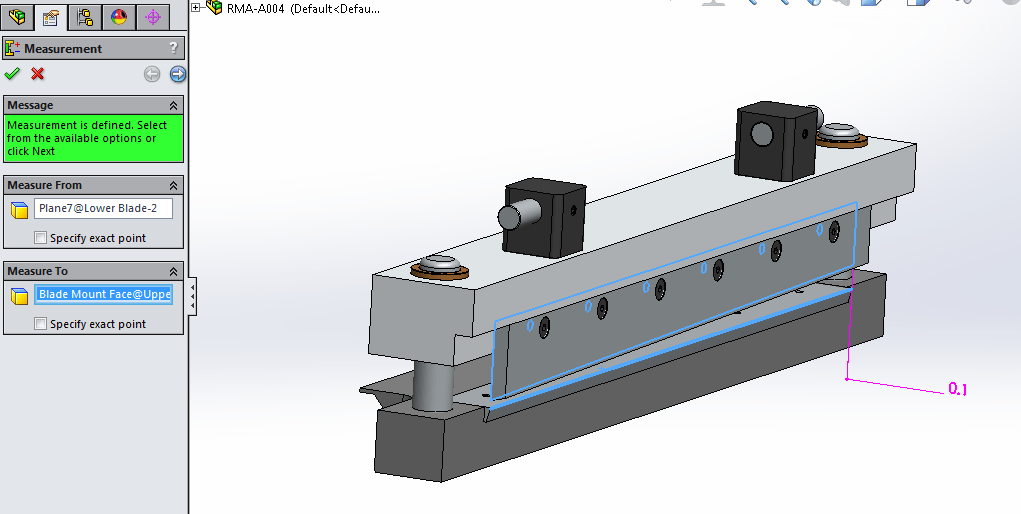

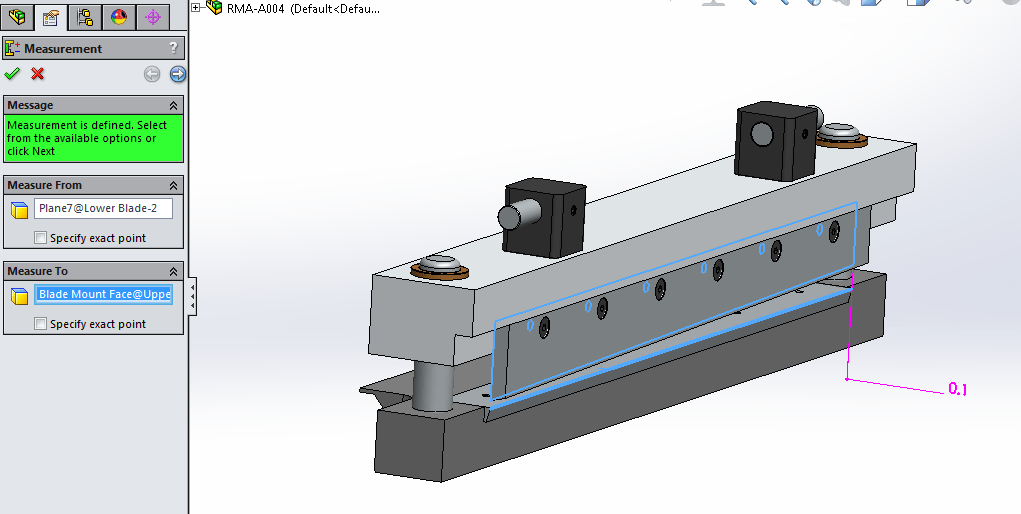

In the Property Manager, pick the 2 faces that you want to set up as

measurement faces. The measurement is the dimension that you are running the

analysis for. In this case, it’s the distance between the front face of the

bottom knife and the back face of the top knife. The nominal dimension is 0.1”

and is highlighted in pink. SOLIDWORKS also gives us a green message letting

us know the measurement is defined. Hit the blue arrow to the top right to go

to the next step.

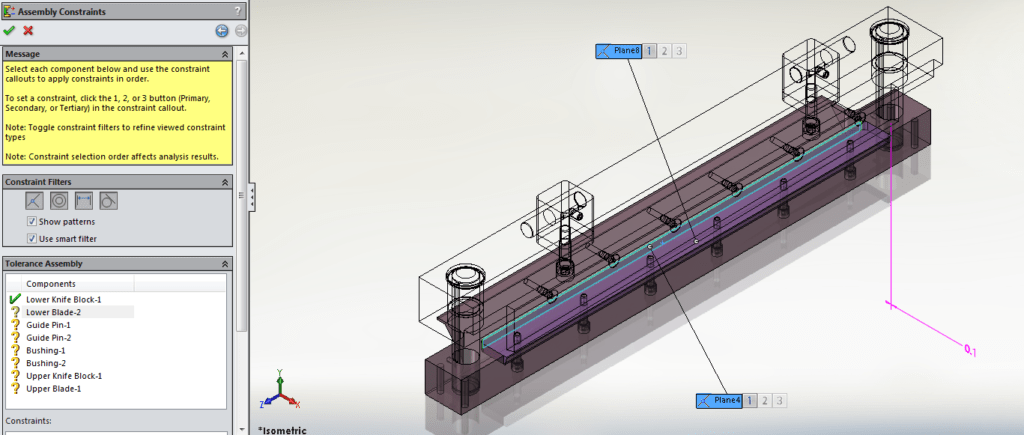

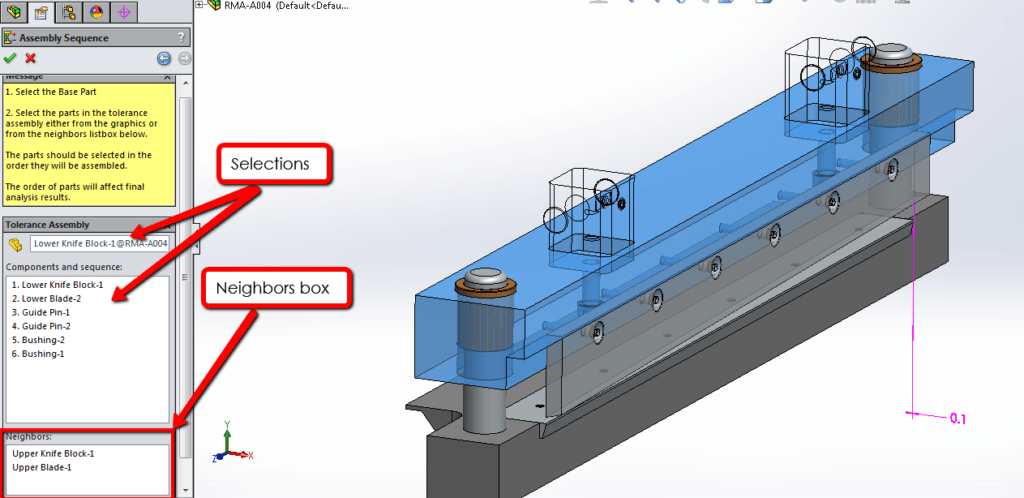

Step 2 is telling TolAnalyst the order/sequence of how the assembly goes

together. Mimicking the real world assembly sequence, it will be as follows:

the lower knife block, the lower blade, the 2 guide pins, the 2 bushings, the

upper knife block and finally, the upper knife. Just select the parts in the

proper order, and you can right click on a part and delete it if it’s out of

sequence. While you are selecting, the rest of the parts in the assembly

remain transparent until they are selected. SOLIDWORKS also provides you with

a “Neighbors” box which you can use to select parts next to the one you are

selecting, or you can select them from the graphics area.

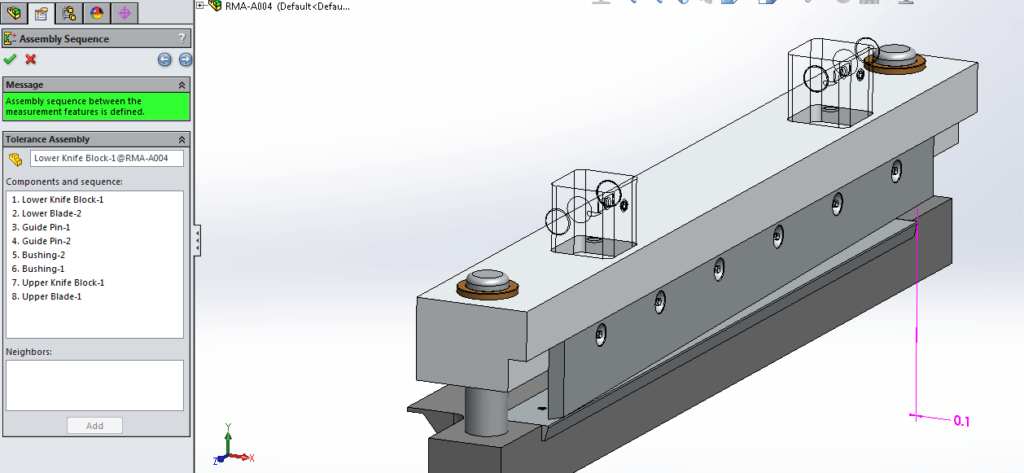

Once you have selected everything, you get the nice green message. Hit the

right blue arrow to go to the next step.

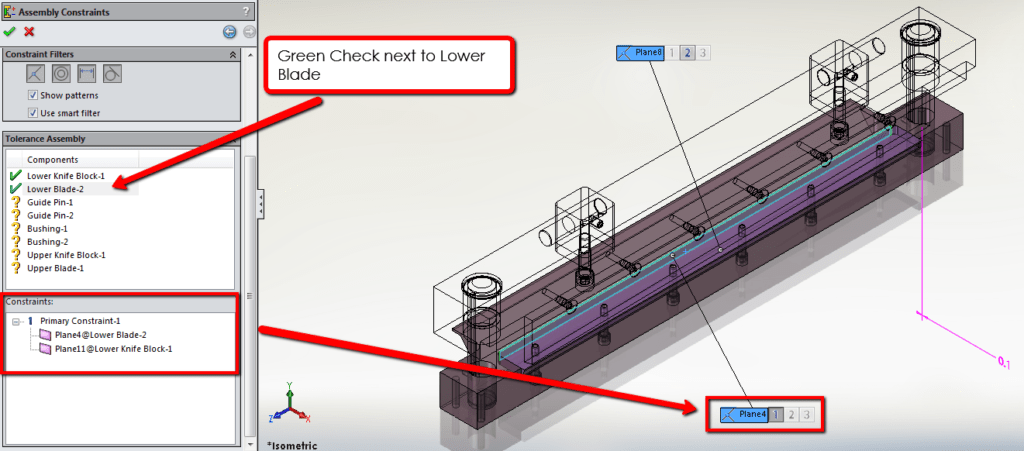

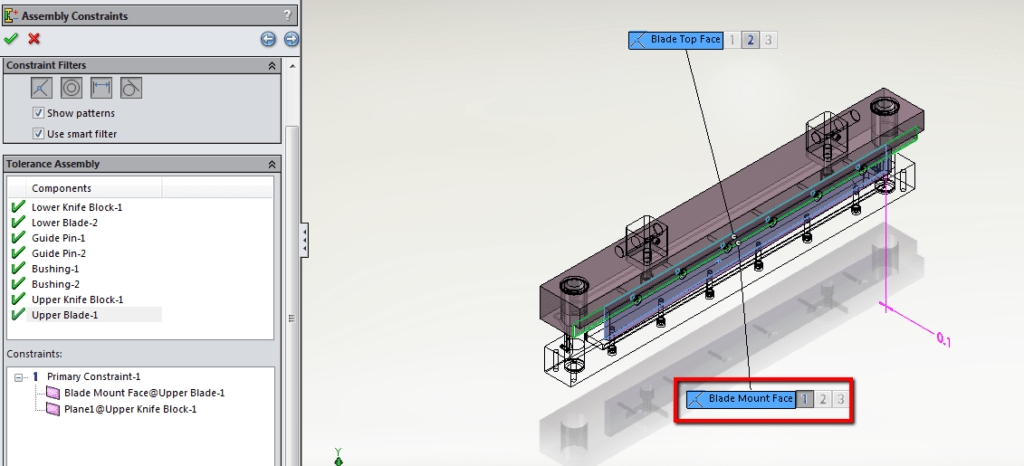

Step 3 is defining the constraints in the assembly. TolAnalyst looks at the

mates within the assembly for these constraints, which will define how the

components are held together. Pick from all the available mates to specify

primary, secondary and tertiary constraints depending on real world

conditions. The first component is the lower knife block, which is fixed due

to it being the first component in the sequence from the previous step, so we

need to set up the constraints for the next component, which is the lower

knife blade. You can see from the image, there are 2 mates to pick from, one

on the bottom of the blade and one on the back of the blade:

You can pick both of these constraints, but you really only need to constrain

the blade in the X (red axis) direction, since the blade moving up and down in

the Y direction won’t affect the tolerance stack up. If you hover over the

flyouts, the faces that are being covered by that constraint highlight in

green. Once you pick 1 or more constraints, the Component in the Property

Manager has a green check next to it. Also, under that Components window, the

Constraints window shows the primary, secondary and tertiary constraints and

what faces they are between.

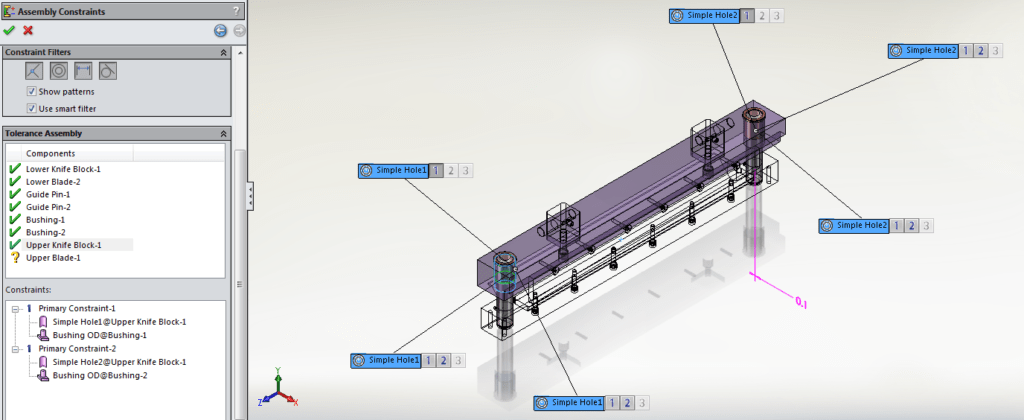

After that, it’s just a matter of selecting the constraints for the other

components. Click on the component, see what constraint or constraints pop up

in the Graphics Area, and then select the number on the flyout. 1=primary,

2=secondary, and 3=tertiary. You can specify the constraint filters that you

want to use, or just let SOLIDWORKS show all and pick from there. Everything

in this assembly is pretty straight forward until you get to the Upper Knife

Block. It has 6 possible constraints to choose from. This is where the green

highlighting becomes key, so that we can pick the constraints between the OD

of the bushing and the block (confirmed by the Constraints box).

Just one last part to select, and that is the upper blade and its mount face.

Next, I just have to hit the Next arrow again to run the study… and that’s

where I’ll end this article (cliffhanger!)

Stay tuned for Part 3, and if you prefer, you can see my

YouTube video here. Thanks for reading!