SOLIDWORKS Simulation has powerful structural and thermal capabilities and puts them in the hands of everyday designers and engineers directly through the SOLIDWORKS interface. This allows them to quickly iterate through model variations while in the design or conceptual phase and select the best variant. There is a wide range of SOLIDWORKS Simulation capabilities and a super easy-to-use interface making it simple to learn and apply to your model.

Ease of use and capabilities are often at odds, however, and sometimes our analysis needs to go beyond what these tools can do. What if you want more element types, or maybe you must simulate something breaking (fracture mechanics) or some other high-end need like this example with highly deforming geometry and lots of contacts.

Did you know that Dassault Systemes offers more simulation tools than SOLIDWORKS Simulation? They offer a complete portfolio of tools for simulation under the SIMULIA brand, including a structural analysis package called Abaqus that excels in non-linear and dynamic studies. You can get access to this technology a number of ways; there are locally-installed versions and some brand new cloud-based packages available to take your analysis to the next level.

Recently I had a chance to give it a try and here are two studies that really benefit from the extended capabilities.

Fracture Mechanics

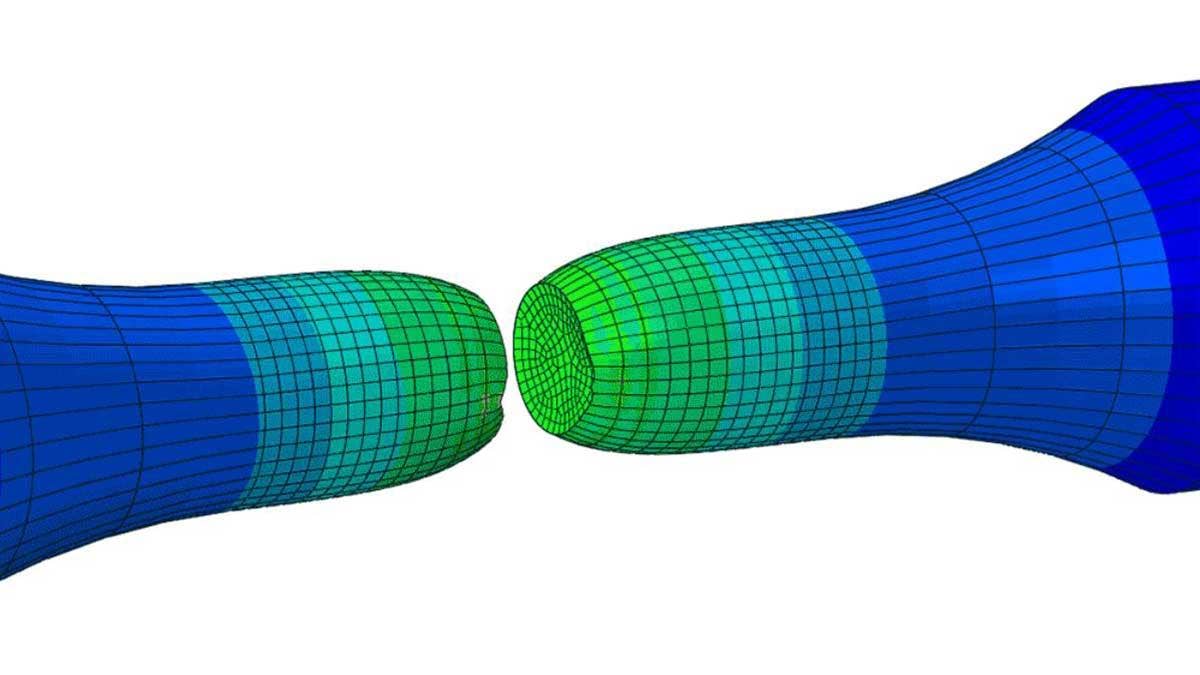

This first example shows a typical tensile test specimen that I was interested in simulating all the way through breakage. The analysis setup was very familiar, including all the usual material properties you’d expect in a non-linear study. The boundary conditions were just like I’m used to; one end was fixed and the other end was moved so that the specimen was put in tension. What was different was the ability to add a damage model to the material. This allows us to model the failure by removing elements from the analysis that exceed the limits of our damage model.

Another difference was the mesh; this example takes advantage of a 20-node quadratic brick. Not only can we use more element types, but you can also manipulate the mesh with maximum control. Zooming in to the break you can see an element has been removed to create a stress riser. Notice the necking behavior you can see in a real tensile test just before failure – so cool!

Efficient Contact Solutions

This next example is a lattice structure that has become very popular due to the availability of 3D printing over the last few years. I’ve been able to print a few of these on our 3D printers, and they’re just so cool, compliant and lightweight, like nothing I’ve ever made before.

To get a better feel for how this structure will work, I set up a simple compression study. One of the challenges of this kind of simulation is the contact. It can be very difficult for a user to determine how it will interact so we can set it up efficiently, and there’s just so much contact that solvers can have a really difficult time converging on a solution. Fortunately, this was super easy using a general contact model that doesn’t require users to choose the faces that will interact. The solver figures all of that out for you. It also handled this analysis with no problems even though it had massive amounts of contacting elements to deal with.

These studies highlight a few common reasons SOLIDWORKS Simulation users look to the SIMULIA brand for additional capabilities. By utilizing the advanced damage models, we were able to accurately mimic the tensile test to break our specimen, and using the efficient contact tools we were able to crush a lattice structure. I’m looking forward to learning more about these advanced tools and taking advantage of their capabilities!

Visit our website if you want to learn more about these tools and if you have any questions, don’t hesitate to contact us at Hawk Ridge Systems. Thanks for reading!