When it comes to engineering, there are many factors that contribute to creating your best designs. Not using the right software, for example, can result in a more time consuming and costly design process – especially when it comes to analysis. Just like how having the right tools in your tool bag can save time and money with repairs around the house, upgrading to a more advanced version of SOLIDWORKS Simulation can help you make better design decisions.

Here are the five most popular reasons that users make the switch from SOLIDWORKS Simulation Standard to SOLIDWORKS Simulation Professional:

Materiality

SOLIDWORKS Simulation Standard includes an expansive library of materials to reference and use for your studies with the ability to create your own. Of course, when it comes to creating your own material, you need to find data to reference. That can sometimes be a daunting task.

With SOLIDWORKS Simulation Professional, you have access to the Materiality Web Portal, which includes an additional database of materials for you to reference and allows you to import into SOLIDWORKS Simulation. It even helps you find the correct data you need based on the type of study (static, frequency, buckling, etc.), the material model (linear elastic, nonlinear elastic, etc.), class (metal, plastic, etc.) and even subclass.

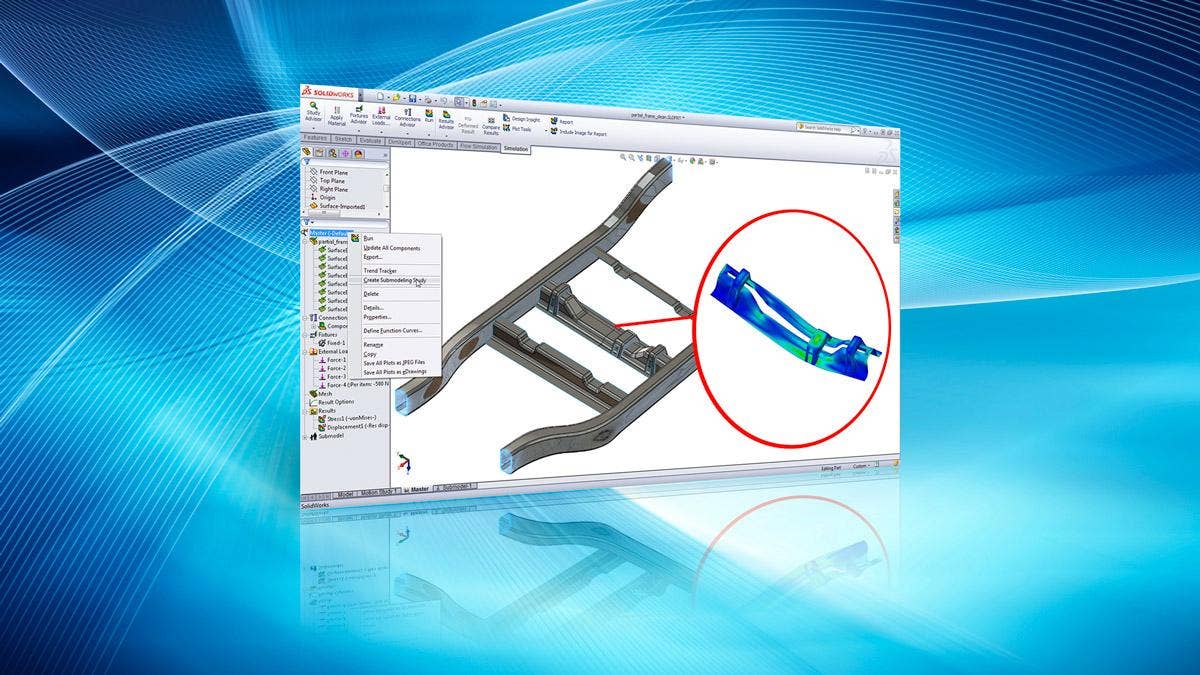

Design Study Optimization

With SOLIDWORKS Simulation Standard, you have the ability to specify discrete values or a range with a specified step size for a various set of variables, such as model dimensions or simulation parameters for both parts and assemblies. These variables will be combined so you can see how each combination affects the results for your design more quickly and easily compared to setting up and reviewing individual studies yourself.

If you already know a goal you need to achieve with your design, such as maximizing the factor of safety or minimizing the mass, and want to check a range of values for various variables to find the best combination that meets your goal, Design Study Optimization in SOLIDWORKS Simulation Professional can help.

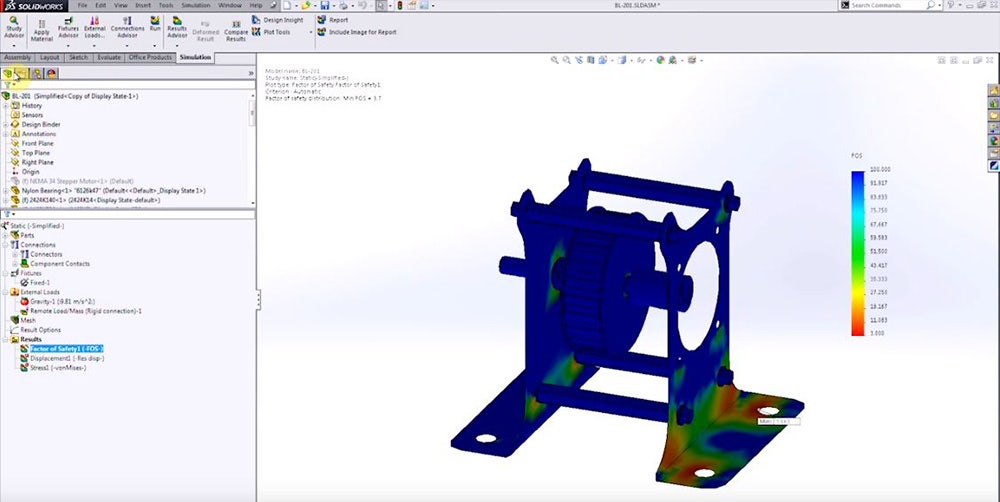

Topology Optimization

It isn’t easy to come up with new designs to solve a problem while meeting specific design criteria. You can use SOLIDWORKS Simulation Standard to understand whether one of your designs meets a design criteria, but knowing what changes need to or can be made to your design based on those results may not come to you so easily.

SOLIDWORKS Simulation Professional has a tool called Topology optimization that can help you find a design that can meet your design criteria for factor of safety (FOS), strength, displacement and even manufacturing controls.

Frequency Analysis

A linear static analysis can be used to obtain stresses and displacements, but what if your design relies on understanding what frequencies to avoid to prevent catastrophic failure? With SOLIDWORKS Simulation Professional, you have the ability to perform a frequency analysis to find those frequencies as well as look at the associated mode shapes.

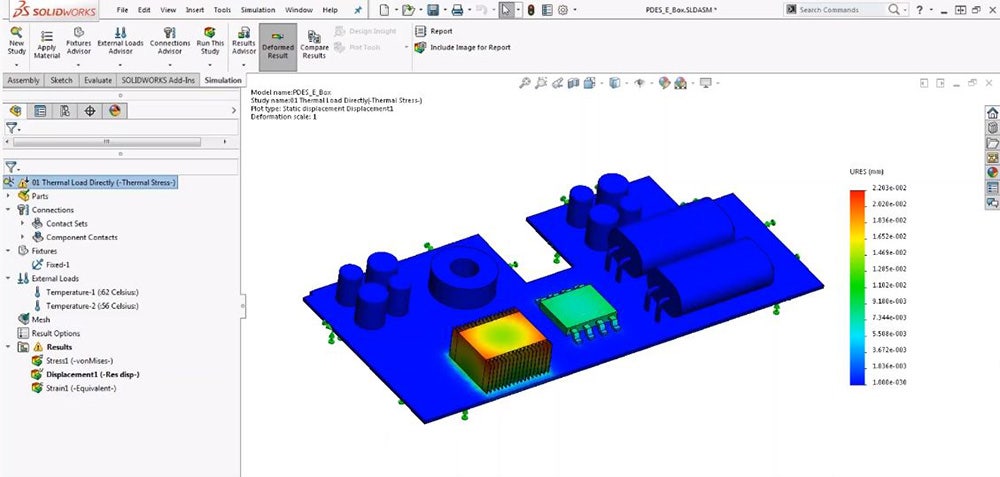

Thermal Analysis

If your designs rely on understanding how temperatures can affect performance, SOLIDWORKS Simulation Professional allows you to run a thermal analysis and account for thermal effects such as convection, conduction and radiation. You can then see how the thermal loads you define in your analysis affect the temperature distribution across your design. You can even take the temperatures you get from a thermal analysis and apply it to a linear static analysis to understand the stresses due to those temperatures.

Still not convinced on the value of upgrading to SOLIDWORKS Simulation Professional? Please contact us and let us address any concerns or questions you may have. Thanks for reading!