This is part 2 of a 3 part SOLIDWORKS Simulation Symmetry discussion. Check

out the

first part here

for the basics of using symmetry. In this post, we’re going to look at

applying symmetry to non-orthogonal planes and shell elements.

|

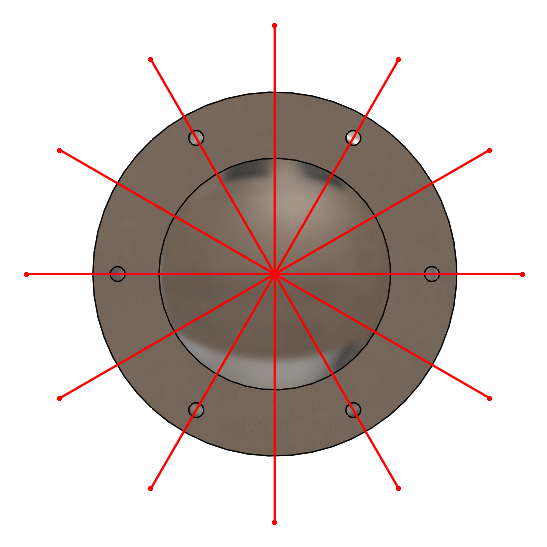

The cylindrical tank above will serve as our example. The model has circular

symmetry with the exception of the 6 holes in the base.

|

Looking at a bottom view, we can see that we have 6 planes of symmetry.

|

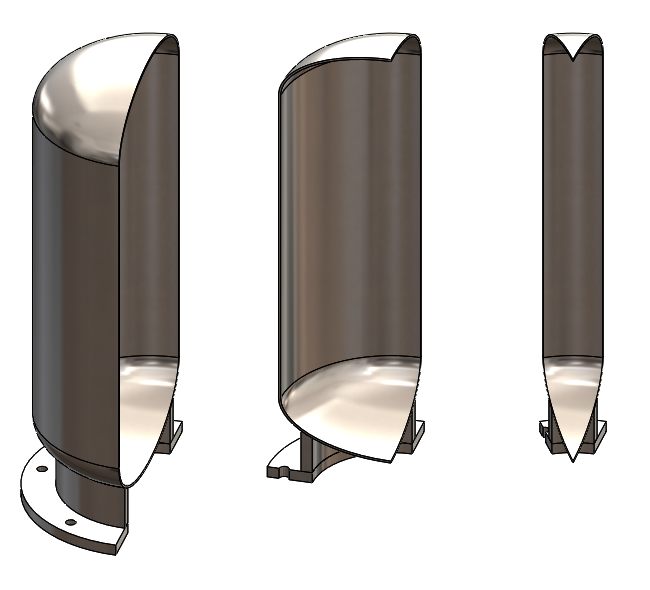

This means that not only can we reduce our tank to a half or quarter model as

we did the first post, we can actually take this model all the way down to a

30-degree slice.

|

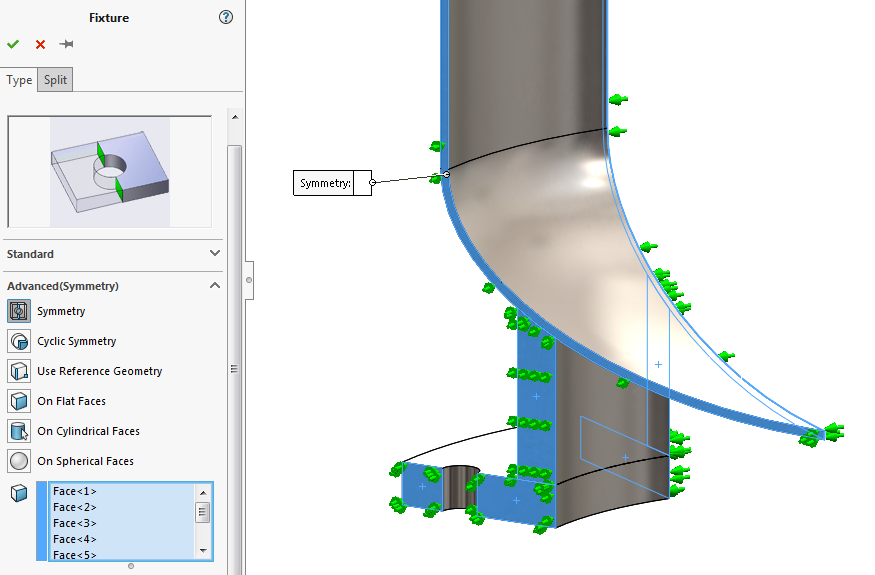

As we discussed in part 1, a symmetry restraint needs to be applied to all of

the symmetry plane faces on both sides of our slice.

|

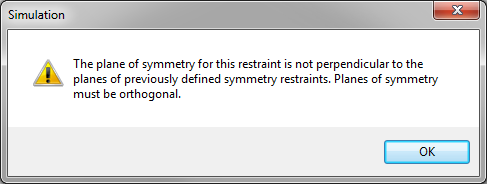

However, trying to do so results in a warning. Symmetry fixtures can only be

used when the symmetry planes are perpendicular to each other. This is the

challenge when using non-orthogonal symmetry.

|

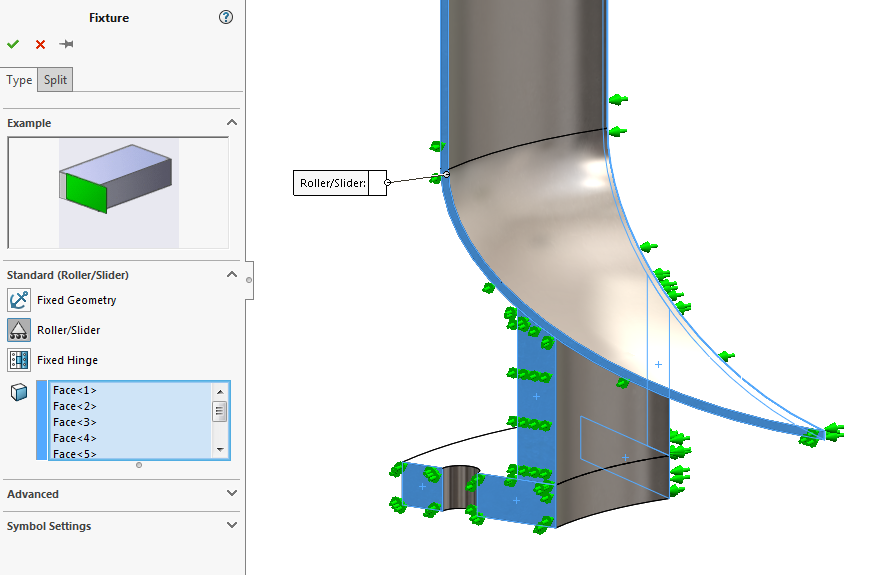

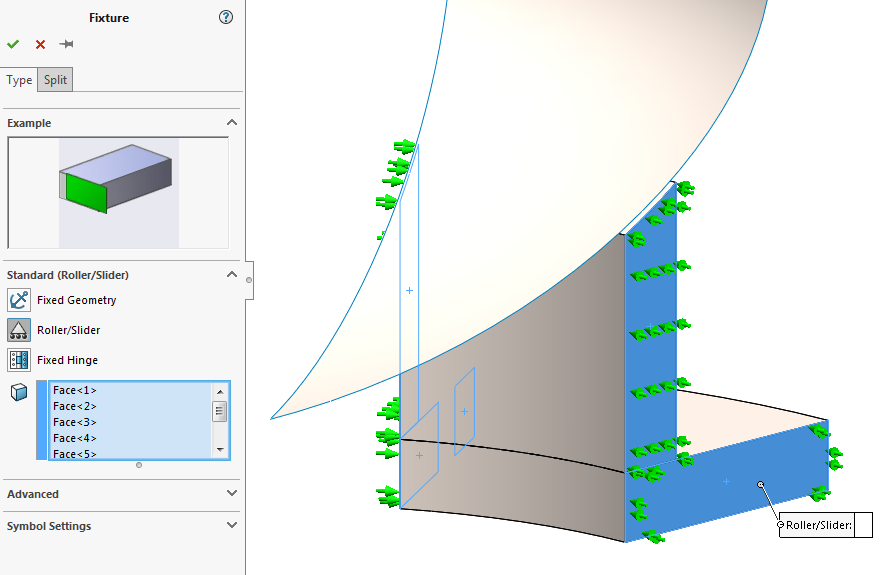

Luckily, it’s a very small challenge. Symmetry fixtures simply restrain

out-of-plane displacement and are functionally equivalent to roller/slider

fixtures (for solid mesh). This means we can simply apply a roller/slider

fixture as our symmetry restraint. Challenge overcome!

|

The only drawback of using roller/slider fixtures instead of symmetry fixtures

is that the option to display symmetric results is not available, but this is

a fairly minor inconvenience.

|

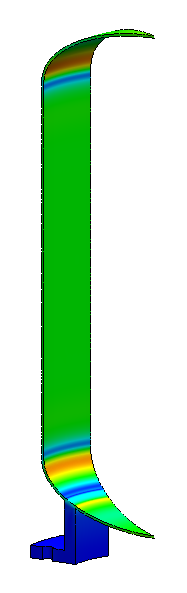

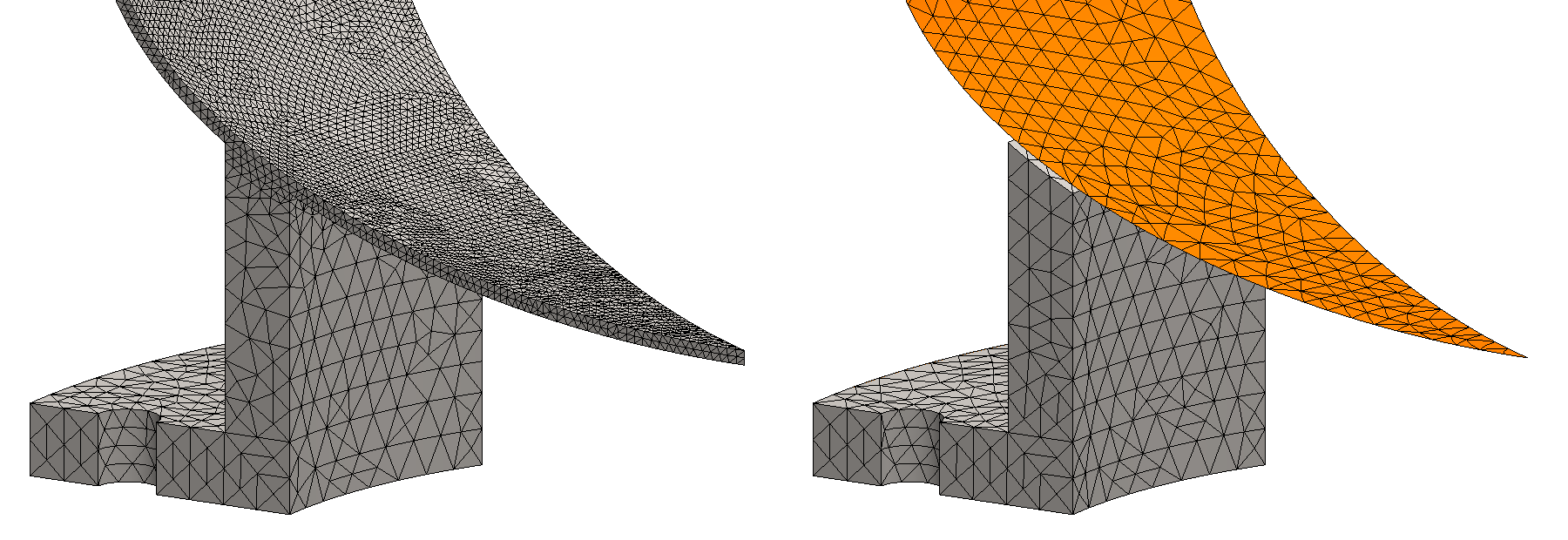

This analysis can be performed more efficiently by using shell mesh elements

for the thin walls of the tank. A shell mesh is easy enough to define by using

faces of the solid model or by using a surface model, but a little bit of

extra care is needed if symmetry is involved.

|

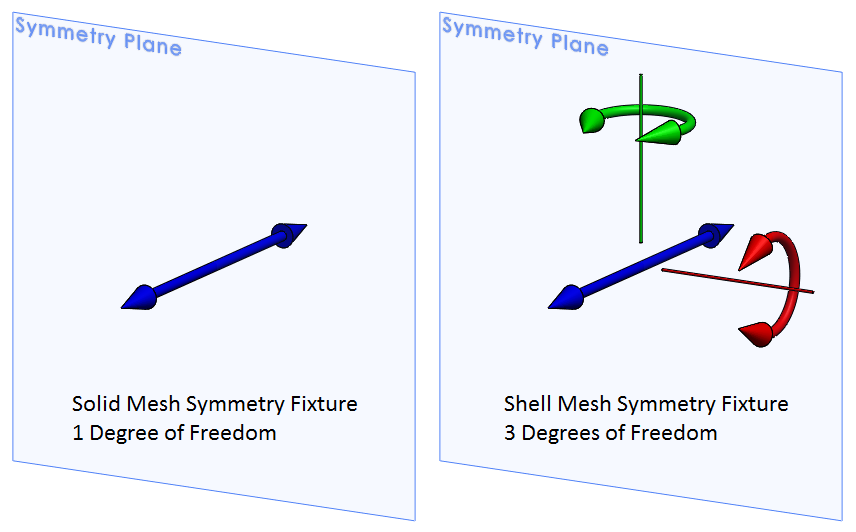

The difference between using symmetry on solid mesh or shell mesh comes down

to degrees of freedom (DOF). Mesh nodes of solid elements can translate in 3

DOF only, while mesh nodes of shell elements have 3 translational and 3

rotational DOF. Symmetry fixtures need to restrain all out-of-plane

displacement and for shell elements, this means constraining 2 rotational DOF

in addition to the 1 translation needed for solid elements.

A symmetry fixture recognizes when it is applied to shell mesh and

automatically takes care of all 3 DOF, so most of the time you don’t really

have to worry about it. In cases where symmetry fixtures cannot be applied,

however, it’s important to understand this difference so that symmetry

restraints can be manually defined correctly.

|

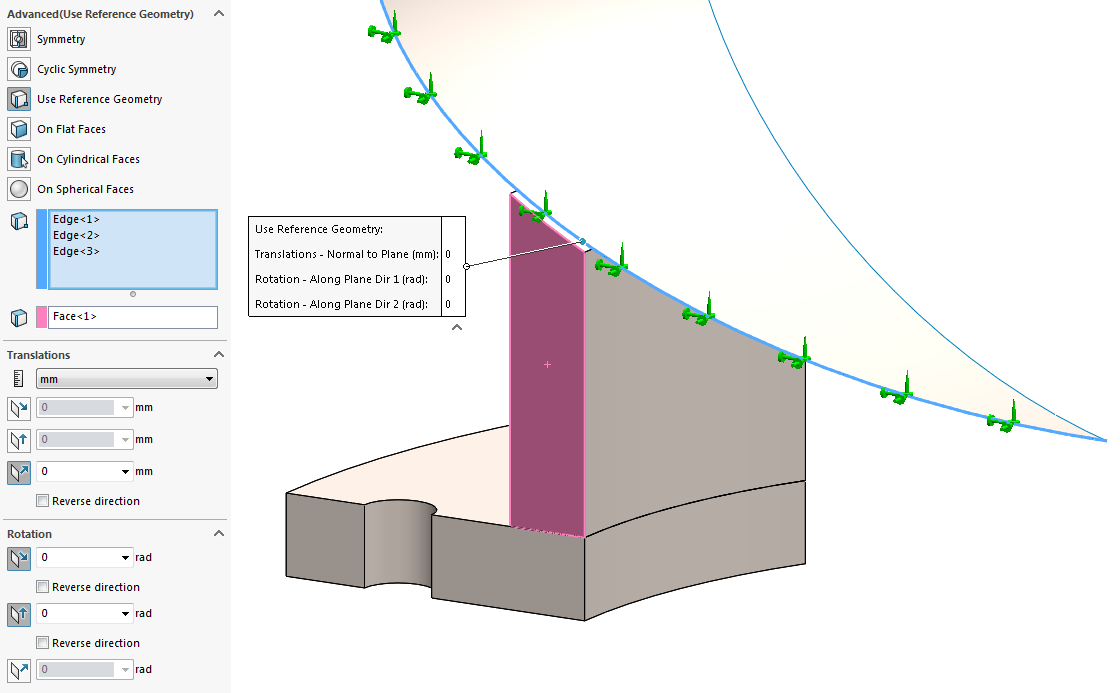

In this example, we can apply an advanced (use reference geometry) fixture to

the edges of the shell on the symmetry plane and use the flat face on the

symmetry plane as the reference. The 1 translation normal to the plane and the

2 rotations about the axes along the plane is set to 0.

|

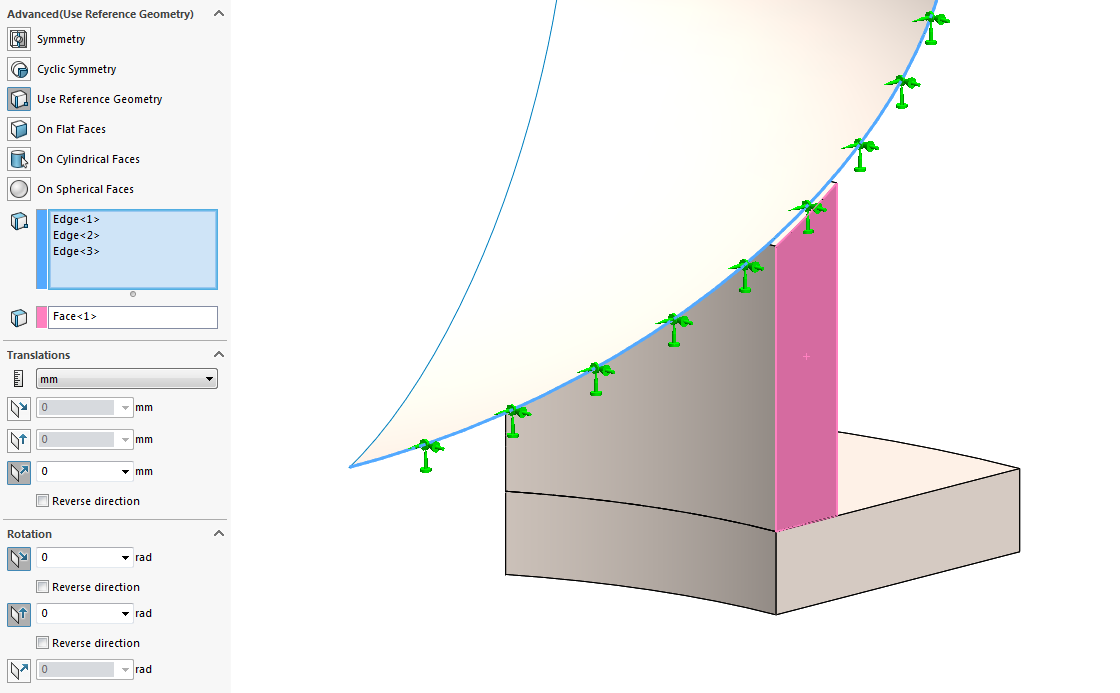

A separate fixture needs to be created on the shell for each symmetry plane,

so we need a similar advanced fixture on the other side of the slice.

|

Like before, a roller/slider fixture can be used for the solid mesh

components.

|

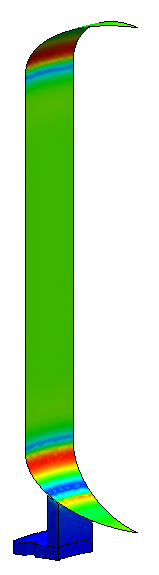

And that’s it! Restraining the correct DOF along the symmetry planes is all

that is needed to use symmetry with non-orthogonal planes or shell elements.

To learn how to take this one step further with 2D simplification, check out

part 3 of this discussion

here. For more information, check out our

YouTube channel

or contact us at

Hawk Ridge Systems

today. Thanks for reading!

Out of interest what is the benefit to using the Roller/Slider method instead of the Cyclic Symmetry?

Good question, Scott. A cyclic symmetry fixture actually allows displacement across the planes where it is applied and is intended for situations where you have cyclically repeating tangential loads, so it wouldn’t be the best choice for the example above. I’d recommend checking out the help documentation to learn more: http://help.solidworks.com/2018/english/solidworks/cworks/c_circular_symmetry.htm