DyeMansion

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

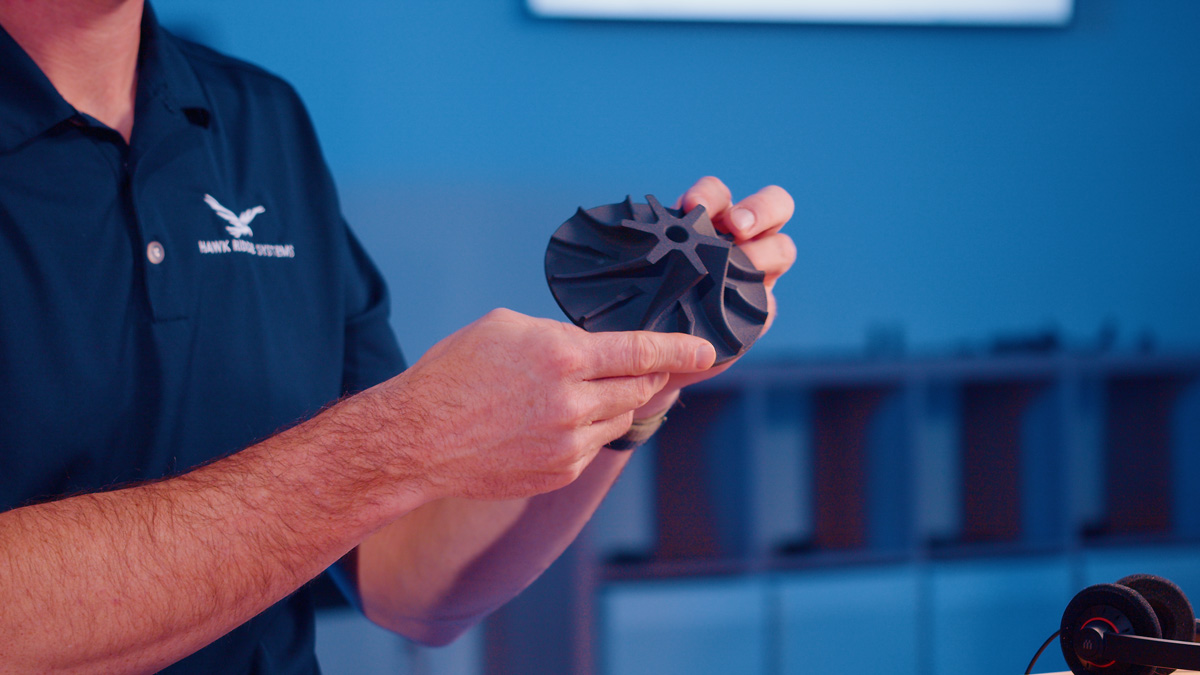

Cleaning

Easily clean and prepare your 3D printed parts for finishing with DyeMansion’s efficient and reliable cleaning process.

Surfacing

PolyShot Surfacing for semi-gloss, scratch resistant parts or VaporFuse Surfacing for fully sealed, injection-molded like parts.

Coloring

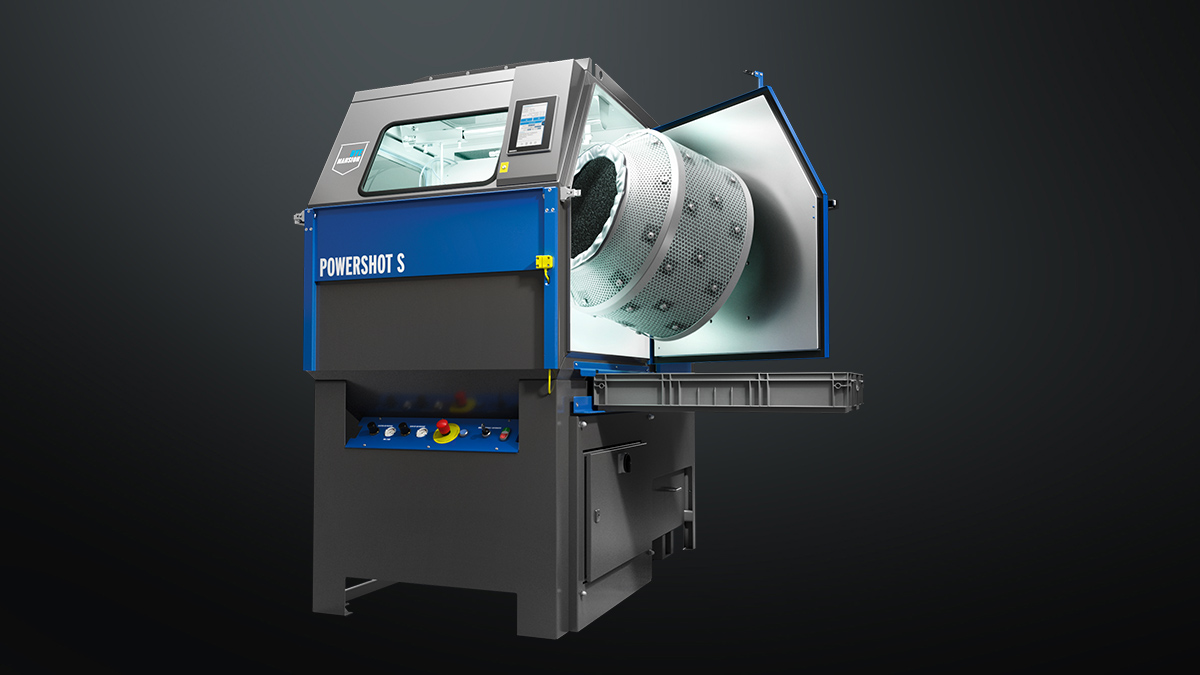

Powershot C

The industry standard for easy and efficient part cleaning. Designed to streamline powder removal for high-precision post-processing, the Powershot C is the perfect fit for diverse additive manufacturing workflows.

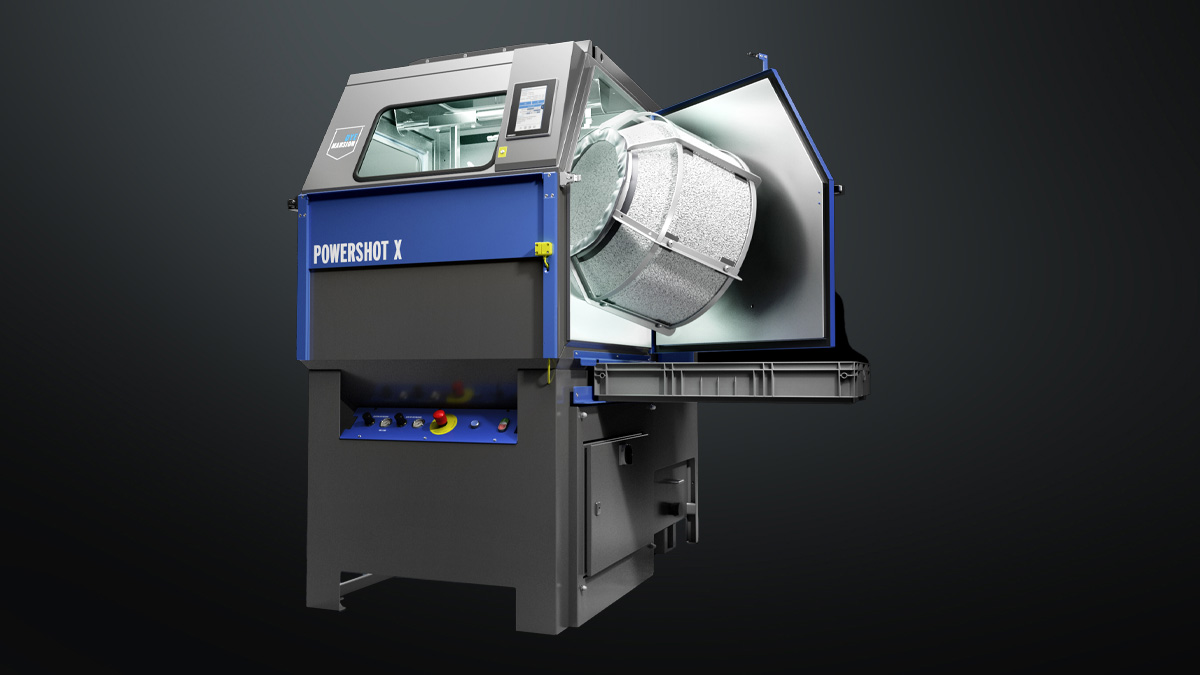

Powershot X

The new generation of the leading blasting system in post-processing: optimal results for every requirement.

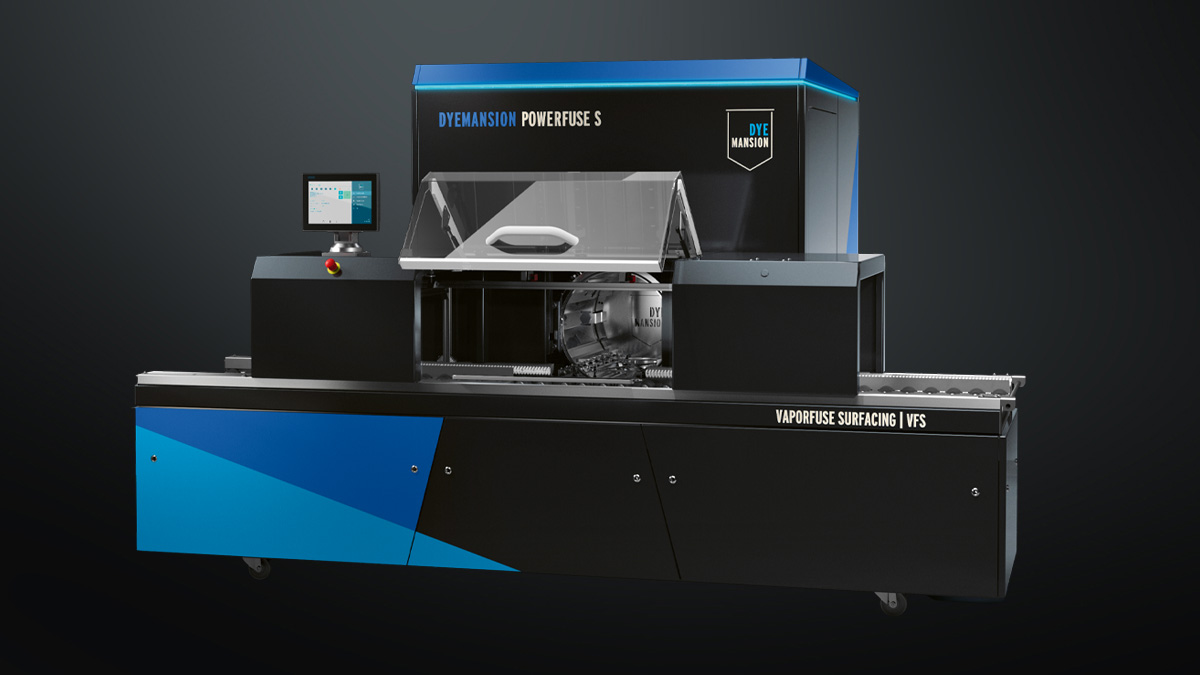

Powerfuse S

Transform 3D printed parts into smooth, sealed, and functional end-use components with sustainable vapor polishing technology for industrial-grade manufacturing.

DM60

The ultimate solution for consistent and scalable part dyeing in industrial additive manufacturing workflows.

Powershot Dual

Enhance efficiency in high-volume additive manufacturing with our advanced system, designed for seamless integration into modern production environments.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Post-Processing Resources

Give Your Printed Part the Finished Look It Deserves

Watch Webinar

Design, Print, Ride – A Product Journey

Watch Webinar

3D Printer Buyer’s Guide

Download Guide

How Do HP Multi Jet Fusion 3D Printers Work?

Download GuideFrequently Asked Questions

Services & Customer Benefits

Technical Support

Our dedicated team is here to provide comprehensive support, including thorough pre-installation planning and expert installation services. By leveraging our expertise, we ensure a seamless process to swiftly set up your DyeMansion system, allowing you to get up and running with ease.

Unmatched Training

Our team is committed to your success with your new DyeMansion system. We’ll provide thorough operational training to ensure you’re fully equipped to make the most of its capabilities and seamlessly integrate it into your workflow.