SOLIDWORKS has a unique and powerful type of assembly component pattern for

setting up patterned components along an open or closed path to dynamically

simulate a roller chains, cable carriers, and power transmission systems. This

new feature was introduced in

SOLIDWORKS 2015.

In this 3-part series, we’ll take a look at how to set up a generic energy

chain along with special cases and considerations for performance and optimum

behavior.

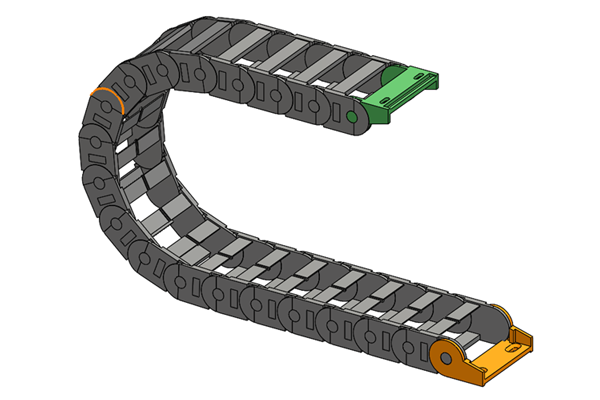

Before we start to assemble this thing, let’s first look at how the individual

components are mated together. The fixed bracket (orange) is fixed to the

origin. There is a component that contains only a sketch (purple) to define

the shape, or path, of the chain that is mated to the Front and Top planes,

which means it can move back and forth (parallel to the Right plane). The

floating bracket (green) has only a parallel mate to the top plane. And the

link component (grey) has no mates applied.

Now when we choose the Chain Component Pattern, there are 3 options: Distance,

Distance Linkage, and Connected Linkage.

Distance

individually or with the selection manager, then define the number of

instances, or choose to fill the entire length of the path.

Next, choose the component, its spacing, and its Path Link and Path Alignment

Plane. The Path Link is a location reference that “attaches” the component to

the path. In this case it’s a circular edge, which defines an axis that

pierces the path. The plane in the link is centered and sets the orientation

of the part to the path.

If you fix the component with chain path sketch, you can can drag the link

along the path and see the entire chain move. If the path sketch part is free

to move left and right, you can drag that component and the chain will move

accordingly. In this mode, the patterned components are oriented exactly the

same as the “seed” or original link, so if you are dragging the link and it

rotates (because it is not entirely defined by selections in the feature), the

components in the chain, regardless of the position along the path, will also

rotate in the same way.

Distance Linkage

along the path, but still allows for a defined spacing. In this case, we’ll

just select the opposite circular edge of the link for the second Path Link

which will fully attach it to the path.

Now, when we drag the path or the link, the chain components follow the path

and stay oriented to it.

Connected Linkage

variable and connects the links. Let’s define this chain to have 19 links.

The feature uses the same two Path Link selections to connect the instances of

the link component to each other.

To finish the chain and make it something you can use in a higher level

assembly, you would mate the first link to the fixed mounting bracket, and the

floating mounting bracket to the end of the chain then when we float the path

sketch component, the energy chain behaves realistically. It even stops when

it reaches the limits of the path.

When adding this energy chain sub-assembly to a top level assembly, there are

a couple of things to do:

-

Since the movement of the component that contains the path sketch is what

determines how and when the chain moves, make sure that component is mated

correctly to other parts in the assembly that will drive the movement of the

chain. -

In order to allow this glorious chain motion, you must set the chain

sub-assembly from Rigid to Flexible.

In Part 2 in this series, we’ll take a look at special use cases of the chain

component pattern such as a closed loop bicycle chain with two types of links,

rotary motion, and using in-context sketches to define the path.