An Engineers View: How AI Fits into the SOLIDWORKS Workflow

A practical, no-hype webinar that shows exactly where AI and intelligent assistants save real time in everyday modeling, assembly, and drawing workflows — with live examples you can apply to your workflows.

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

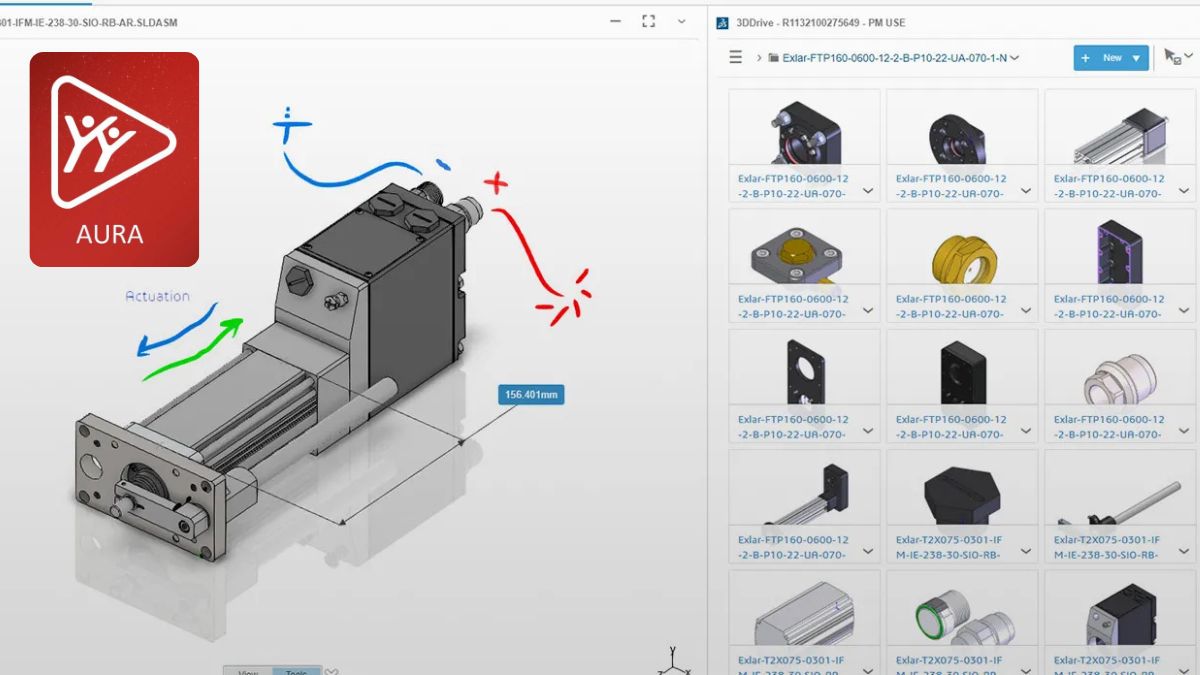

Practical AI for SOLIDWORKS Users: Live Engineer Demo of Real-World Time Savers

AI is everywhere, but most SOLIDWORKS users still aren’t sure how to use it day-to-day.

Join two Hawk Ridge Systems engineers as they open real part and assembly files and walk through exactly where AI and intelligent assistants save time, cut repetitive work, and help you make better design decisions — all inside the workflow you already know.

Hear practical tips like which tools work completely offline inside SOLIDWORKS and which ones live in the cloud; and how to find any command or FeatureManager option in seconds instead of digging through menus. Plus get simple, 5-minute setups you can start using the same day.

No fluff. Not a prompt-engineering class. Just two engineers showing what’s working right now in SOLIDWORKS 2025 and 2026.

What You Will Learn

Precisely where AI and assistants naturally fit

Into everyday modeling, assembly, and drawing tasks

How to reduce repetitive work

Like fixing mate errors, cleaning up sketch relations, and reordering features

Context-aware AI suggestions

For optimal hole patterns, sheet metal bends, draft angles, fillets, and more

Real-world before-and-after examples

Of the same parts designed with and without AI assistance

Your Speakers

Scott Woods

Sr. Product Manager, 3DEXPERIENCE and Mechanical Design Tools Scott Woods has been with Hawk Ridge Systems since 2008 and has over 20 years of SOLIDWORKS experience, holding degrees in both Technical and Visual Communications. When he is not working with our customers to find solutions to their design challenges, he can often be found using his design skills to create 3D printed beehives.

Joseph McDiarmid

Joe McDiarmid is the Enterprise Technical Account Manager at Hawk Ridge Systems, managing the rapidly growing and evolving needs of our largest and most complex customers. He is a 12 year veteran of HRS with a B.S. in Aerospace Engineering from New Mexico State University, and an experienced SME in most SOLIDWORKS and DS applications, ranging from CAD & Electrical to AI and Cloud 3DX Roles. He frequently spends time visiting customers to resolve real-world challenges that weave through design, documentation, business processes, and manufacturing through technical mentorship, engineering services, and consultative assessment reviews. In his spare time, he swaps engines, restores classic cars and motorcycles, and makes wiring harnesses in-between playing with his 4-year-old son Nico.