The Role of Simulation in Lightweighting Vehicle Components

Explore the critical role of simulation in designing lighter, more efficient vehicle components.

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

The Role of Simulation in Lightweighting Vehicle Components

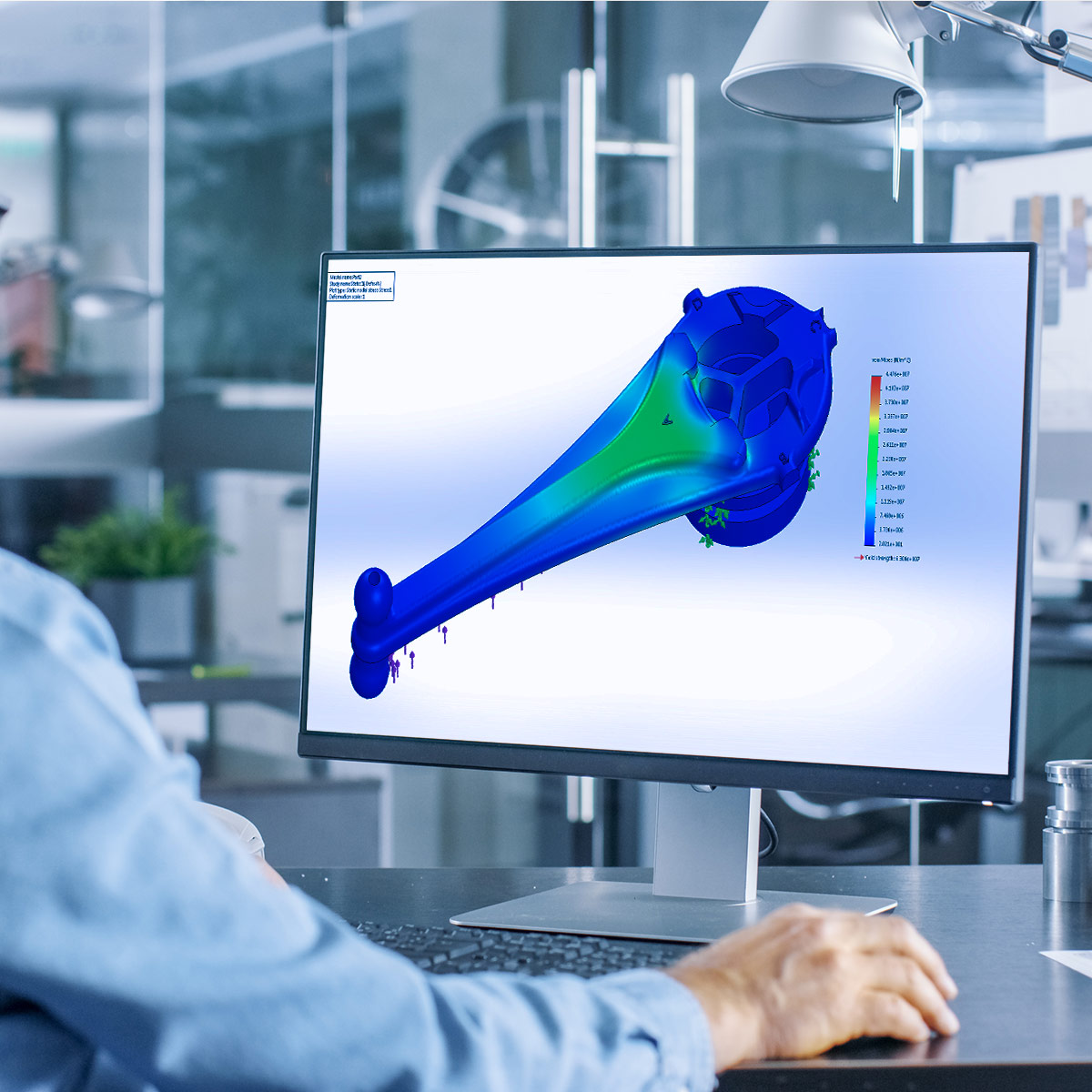

Reducing weight is a top priority in product design across industries, especially in automotive manufacturing. As OEMs strive for lighter vehicles to achieve fuel efficiency and extended range, suppliers must balance weight reduction with uncompromised safety and durability. Simulation is the key to meeting these challenges, enabling engineers to evaluate new materials, optimize structures, and navigate performance trade-offs effectively.

In this session, you’ll discover how simulation empowers smarter, data-driven design decisions, plus techniques for lightweighting automotive components without sacrificing quality.

Don’t miss this opportunity to learn how simulation is transforming the automotive industry.

What You Will Learn

See how simulation drives smarter designs

Use SOLIDWORKS simulation to test materials and optimize structures before building prototypes

Learn how design studies speed development

Run multiple simulations at once to compare options and reduce iteration time.

Organize and interpret results efficiently

Consolidate simulation data in one view to improve collaboration and decision-making.

Your Speakers

Kenny Truong

Kenny Truong has been an Applications Engineer at Hawk Ridge Systems for the last 4 years. He is a Certified SOLIDWORKS Expert and a Certified Simulation Professional. He teaches a variety of simulation courses and aids in developing new training materials. In his free time, he’ll often use SOLIDWORKS and simulation to help design and build DIY projects for his own car.

Terence Woo

Terence Woo has extensive experience with the wide range of SOLIDWORKS and SIMULIA analysis tools and has helped our customers solve problems across multiple industries. He is located in Vancouver, British Columbia, and when he isn’t working on simulation models, spends his free time skiing, golfing, rock-climbing, and playing hockey.