Making 3D printing a go-to solution for manufacturing at any volume

How 3D printing revolutionizes manufacturing, plus expert insights on additive technologies, cost-effective solutions, and scalable production for any volume.

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

Revolutionizing Manufacturing with 3D Printing

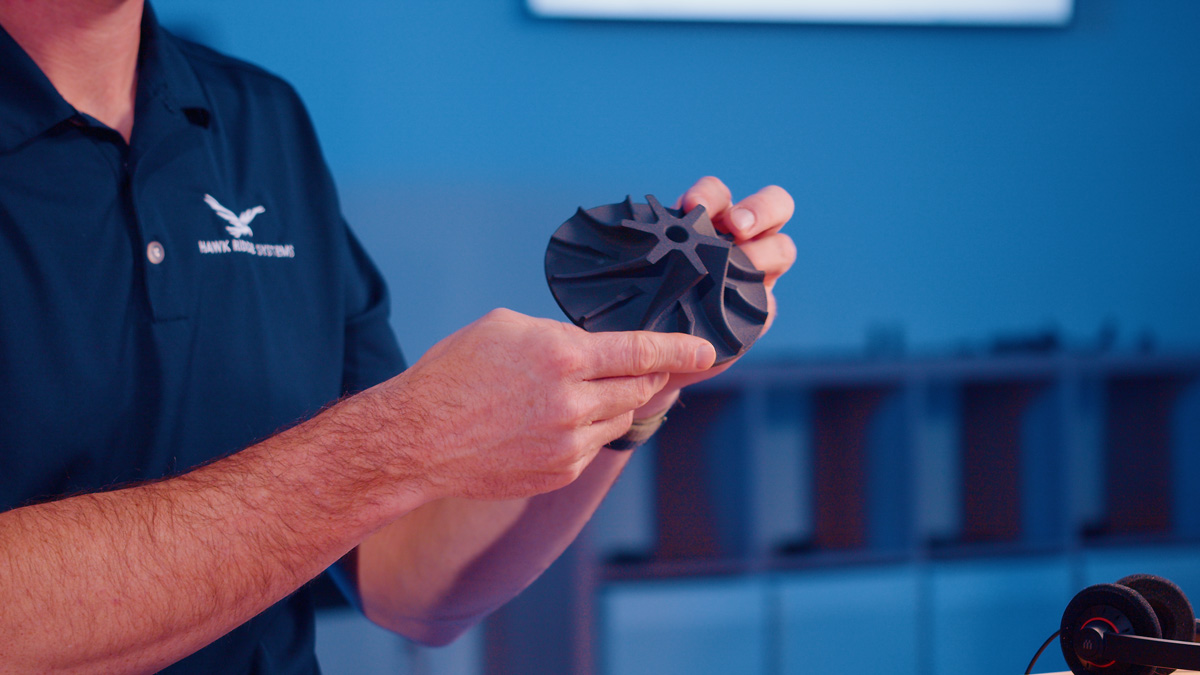

Additive manufacturing has transformed from a niche prototyping tool into a game-changer for mass production. No longer limited to complex, one-off parts, today’s cutting-edge additive technologies rival traditional subtractive methods like machining—offering unmatched flexibility, efficiency, and cost-effectiveness. Watch as three industry experts share their insights on leveraging 3D printing for manufacturing at any scale.

What You Will Learn

Unleash Design Freedom

Create intricate geometries impossible with conventional methods.

Scale with Confidence

From prototypes to high-volume production, additive manufacturing delivers.

Optimize Costs

Find the economic sweet spot for your production runs with the right technology.

Your Speakers

Donte Wesly

Donte is a 3D Printing Application Engineer at Hawk Ridge Systems specializing in HP and Markforged technologies. Donte has experience using additive technology for prototyping and production parts in the motorcycle industry.

Justin Hopkins

Justin Hopkins is the AMS Applications Engineering Manager with HP Inc 3D, where he plays a pivotal role in helping companies revolutionize their manufacturing processes through the integration of cutting-edge technology. With a deep understanding of the power of additive manufacturing, Justin works closely with businesses to unleash their creative potential and bring their innovative ideas to life.

Jon Toews

Jon leads A3D Manufacturing. A complete Manufacturing-as-a-Service (MaaS) provider, helping companies bridge the gap between design and production with high-quality, scalable manufacturing solutions. With over 20 years of experience spanning engineering software and manufacturing strategy, Jon brings a unique end-to-end perspective to today’s digital-to-physical product lifecycle.