Custom Designs & Perfect Moldings with 3D Printing and Scanning

See how you can use 3D printing and 3D scanning to easily craft custom molds for low-volume or custom production runs.

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

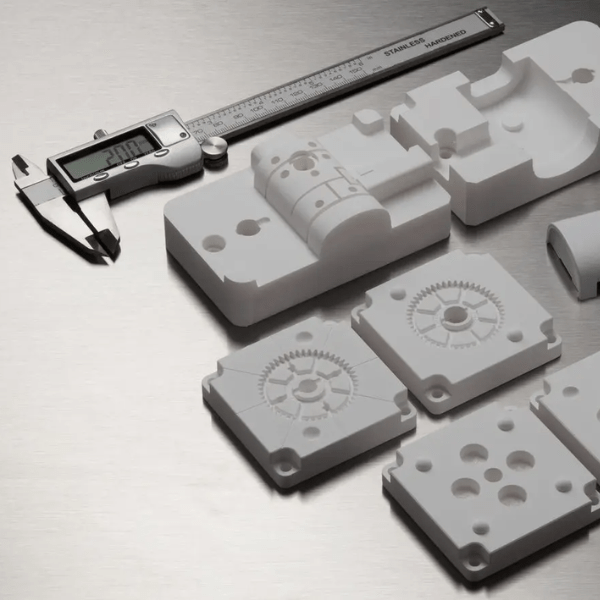

3D Printed Molds for Prototyping

Molds can be expensive and take a lot of time – but the demand for them is high. In this webinar, we’ll show you how you can get quality 3D-printed molds fast for low-volume production runs or highly customized parts.

What You Will Learn

Troubleshooting Tips

How to avoid common pitfalls when it comes to making custom molds.

Mold Preparation

How to prepare custom molds from scan to print.

3D Printing Molds

How extremely fast and cost-effective 3D printed molds from Formlabs 3D printers can be.

Your Speakers

Mathew Fisher

Matthew Fisher is an application engineer who specializes in all things 3D scanning. He began his career as a SOLIDWORKS user, and with extensive experience in 3D printing, Matthew now uses a variety of 3D scanners to inspect, reverse engineer, and create renders of products. With an interest in digital preservation, he also uses 3D scanning in his hobby, capturing unique finds around the city and parks. Matthew serves as Hawk Ridge Systems’ Technical Marketing Engineer.