Beyond Static Analysis: Shock & Vibration FEA for High-Tech Devices

Explore dynamic simulations like FEA and how they improve product durability.

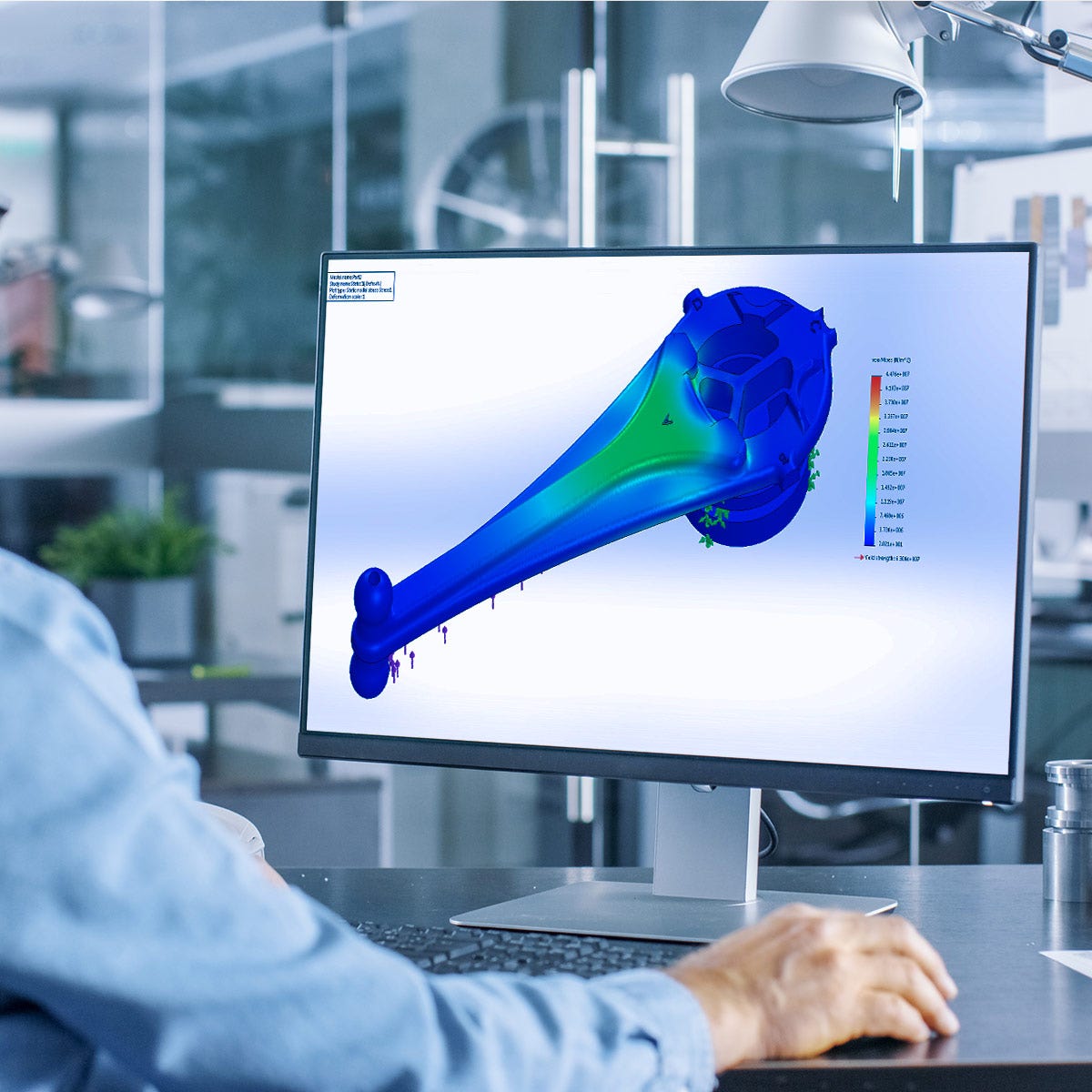

Improve Product Durability with Accurate FEA Modeling

Many engineers rely on static simulations, but in the world of high-tech devices — where reliability under dynamic conditions is critical — shock and vibration analysis is the magic ingredient.

Meeting industry standards and dynamic testing specifications requires accurate finite element analysis (FEA) modeling of transient and frequency-based loads.

In this webinar, we’ll explore why dynamic simulations are often overlooked, how they can improve product durability, and best practices for aligning simulations with testing requirements.

Whether you’re optimizing electronics, aerospace components, or consumer gadgets, this session will equip you with the tools to enhance your designs and meet industry standards.

What You Will Learn

Dynamic Simulations

Learn about FEA for high-tech devices.

Ways to Improve Product Durability

See how dynamic simulations can make your product more durable and help withstand wear and tear.

Best Practices Aligning Simulations

Get best practices from experts on aligning FEA simulations with testing requirements.

Your Speakers

Terence Woo

Terence has extensive experience with a wide range of SOLIDWORKS and SIMULIA analysis tools and has helped our customers solve problems across many industries. He is located at our office in Vancouver, British Columbia. When he isn’t working on simulation models, he spends his free time skiing, golfing, rock climbing, and playing hockey.

Patrick James

Patrick is an application engineer based out of our Mountain View, CA office. He has over 14 years of CAD experience and has been in tech support and training for the last nine years. He specializes in SOLIDWORKS, SOLIDWORKS Simulation, SOLIDWORKS PDM, and SIMULIA and Abaqus.